How to Make Your Own Chicken Feed in South Africa?

85Before purchasing equipment to produce chicken feed pellets, it is recommended that you think about your main feed formula.

View detailsSearch the whole station

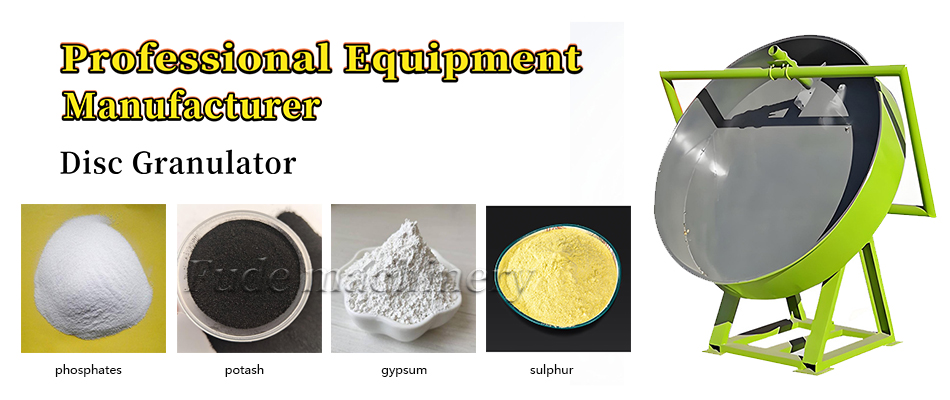

Limestone granules are a critical component in various industries, including agriculture, construction, and manufacturing. The process of transforming raw limestone into granules involves several steps, one of which is pelletization. Among the different pelletization technologies available, the disc pellet machine has emerged as a preferred choice for making limestone granules. This passage will explore the reasons behind this preference, highlighting the advantages and unique features of the disc pellet machine that make it an ideal choice for limestone granule production.

One of the primary reasons for choosing a disc pellet machine for limestone granule production is its high efficiency. The machine operates by allowing raw limestone powder to fall onto a rotating disc, where it is sprayed with a liquid binder. The rotational motion of the disc and the centrifugal force work together to form granules quickly and consistently. This efficient process results in high production rates, meeting the demands of large-scale operations.

Uniformity in granule size is crucial for various applications, particularly in agriculture, where consistent granule size ensures even distribution of nutrients. The disc pellet machine excels in producing granules with uniform size and shape, thanks to its adjustable tilt angle and rotational speed. Operators can fine-tune these parameters to achieve the desired granule size, ensuring consistency and quality in the final product.

The versatility of the disc pellet machine is another significant factor that makes it a preferred choice. In addition to limestone, the machine can pelletize various other materials, such as fertilizers, coal, and metallic ores. This flexibility allows producers to use the same equipment for different applications, optimizing their investment and operational efficiency.

Disc pellet machines come with several customizable features that enhance their adaptability. Operators can adjust the disc’s angle, rotational speed, and the amount of liquid binder used in the pelletization process. These adjustments allow for fine-tuning the granule formation process to meet specific requirements, making the machine highly adaptable to different production needs and material characteristics.

Cost-effectiveness is a critical consideration in selecting pelletization equipment. Disc pellet machines cost typically have lower operational costs compared to other pelletization technologies. The machine’s design ensures minimal waste generation, reducing raw material costs. Additionally, its energy-efficient operation lowers electricity consumption, further contributing to cost savings.

The robust construction and simple design of disc pellet machines result in lower maintenance requirements. The components are designed for durability and ease of access, simplifying routine maintenance tasks. This reduces downtime and maintenance costs, ensuring continuous operation and maximizing productivity.

Environmental considerations are becoming increasingly important in industrial operations. Disc pellet machines are known for their eco-friendly operation. The pelletization process generates minimal dust and emissions, contributing to a cleaner working environment. Additionally, the machine’s efficient use of raw materials and energy aligns with sustainable production practices.

The ability of the disc pellet machine to produce uniform granules with minimal waste aligns with modern waste reduction goals. By optimizing raw material utilization and minimizing off-specification products, the machine helps in reducing the overall environmental footprint of the pelletization process.

The choice of a disc pellet machine for making limestone granules is driven by several compelling factors, including high pelletizing efficiency, uniform granule size, versatility, cost-effectiveness, and environmental benefits. These advantages make the disc pellet machine an ideal solution for producing high-quality limestone granules, meeting the diverse needs of various industries while ensuring operational efficiency and sustainability. If you are interested in our products, please consult us Fude Machinery!

Before purchasing equipment to produce chicken feed pellets, it is recommended that you think about your main feed formula.

View detailsThe quality of feed is an important material to provide the nutrition required for the growth of chicks

View detailsTurning fine potassium chloride powder into easy-to-use granules offers many advantages for fertilizer producers and farmers.

View detailsIn the fertilizer industry, ammonium sulfate is a common and important nitrogen fertilizer widely used in agriculture to provide plants with the necessary nutrients.

View details