In the pursuit of sustainable agriculture, composting hog manure is a practical and environmentally friendly solution.

We will explore in detail the basics of composting, the equipment needed, and the steps on how to convert swine manure into valuable compost.

The central principle of compost production is the transformation of organic materials such as manure and pig urine, mixed with shredded straw, into stable humus through natural or aerobic fermentation. This process is carried out with the help of microorganisms.

Composting Process and Equipment Selection

Aerobic fermentation is crucial for successful composting, especially considering the high moisture content of swine manure. Prior to fermentation, it is necessary to dewater the manure. In this regard, solid-liquid separation equipment is very effective, being able to process 30 to 40 tons per hour. The ideal moisture content for pig manure composting is between 50% and 60%. This equipment ensures that the manure reaches the moisture level required for effective composting.

- The Role of Turnover in Fermentation

Once dehydrated, the next step is fermentation. Regular turning is crucial to promote compost fermentation, as it improves aeration and oxygen supply, stimulating the activity of beneficial microorganisms.

Turning also mixes the inner and outer layers of the compost heap, ensuring an even distribution of temperature, moisture and nutrients, which supports balanced fermentation.

Working principle of solid-liquid separator

The working principle of solid-liquid separator is mainly to utilize mechanical force or physical method to effectively separate solid particles from liquid in the mixture.

Take the common inclined screen solid-liquid separator as an example, the wastewater to be treated through the overflow weir is evenly distributed to the stainless steel tilted screen surface made of wedge-shaped steel bar precision, because the screen surface gap is small, smooth and back clearance, smooth drainage is not easy to block, the solid material is retained, the filtered water out of the gap from the screen plate;

At the same time in the role of the water force, the solid material is pushed to the screen plate at the lower end of the spiral groove, the spiral forward to the extrusion section for re-dewatering, the dewatered dry residue discharged from the discharge port.

At the same time, under the action of hydraulic force, the solid material is pushed to the spiral groove at the lower end of the screen plate, and then pushed forward by the screw to the extrusion section for dewatering again, and the dry residue after dewatering is discharged from the discharge port, thus realizing solid-liquid separation.

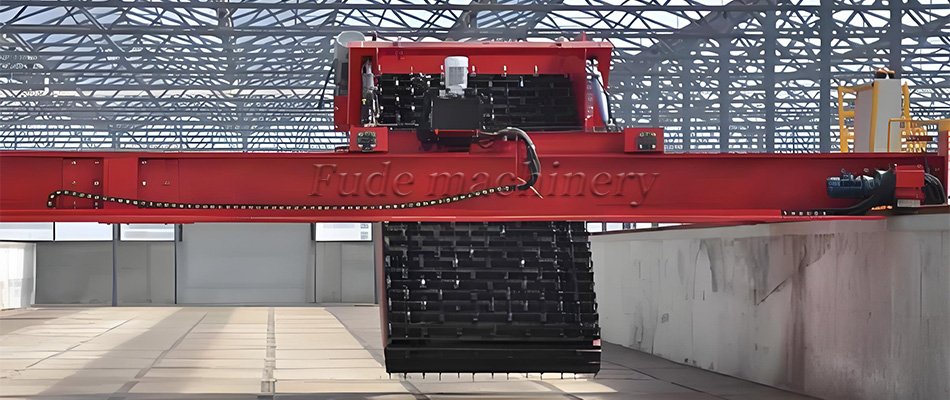

Choosing the Right Tilter

Choosing the right turner can significantly save time and effort. The chain turner is very suitable for composting solid organic waste such as animal manure, sludge and straw waste. This machine is equipped with a frequency inverter to adapt to fluctuations in workload, ensuring stable and efficient operation.

The turning prevents overheating or insufficient fermentation of the compost, thus improving the quality and stability of the compost.

Advantages of Using a Chain Tilter

- Efficient Mixing: Improves uniform distribution of temperature, moisture and nutrients.

- Time Saving: Reduces time and effort required for manual turning.

- Promotes Fermentation: Supports balanced fermentation and prevents problems such as overheating.

- Stable Operation: The frequency inverter adapts to various workloads, ensuring continuous performance.

The working principle of chain turning machine is: under the control of intelligent remote control switch, the equipment travels along the track of fermentation tank, the chain conveyor conveys the organic waste from one end to the other.

At the same time, the multi-toothed chain plate of the turning and throwing mechanism disperses the bottom layer of materials, so that the upper layer of materials fall onto the inclined conveying scraper, the materials are broken up and mixed in the process of conveying, and fall into the tank to form a quantitative displacement after turning over the conveying head;

Turning and throwing parts (chain plate) continuously rotate, continuously seize the materials in the tank and convey them diagonally to the back of the working rack and drop them, so that the materials are reset to the pile. ) continuous rotation, constantly seize the material in the slot and oblique transport to the back of the work frame fall, the material reset the pile, to achieve the material dispersal, flipping and after throwing, so that the material is fully in contact with the air, to promote microbial fermentation and putrefaction;

Along the groove to complete a trip operation, the hydraulic system will be flipped to throw the parts lift, the work frame as a whole back to the initial end, if a wide groove is flipped to throw the trolley to move horizontally to the width of a chain plate distance after continuing to operation, until the completion of the whole trough turning and throwing.

Composting pig manure is a sustainable practice with significant benefits for agriculture.

By understanding the principles of composting and using the right equipment, farmers can effectively transform waste into valuable resources. Using a solid-liquid separator for dewatering and a chain turner for regular turning ensures the production of high quality compost, promoting soil health and environmental sustainability.If you are interested in our products, please consult our Fuder Machinery customer service!

Organic fertilizer equipment,organic fertilizer production line,organic fertilizer equipment factory

Organic fertilizer equipment,organic fertilizer production line,organic fertilizer equipment factory