How to Make 3-10mm Biofertilizer Pellets with a Roller Extrusion Granulator?

Table of Contents

In the realm of sustainable agriculture, the demand for biofertilizers has significantly increased. These organic fertilizers enhance soil fertility and provide an environmentally-friendly alternative to chemical fertilizers. One efficient method of producing biofertilizer pellets is through the use of a double roller extrusion granulator.

This technique results in pellets ranging from 3 to 10mm in diameter, offering a practical size for various agricultural applications. Notably, this process does not require subsequent drying or cooling, making it both energy-efficient and cost-effective.

Understanding Roller Extrusion Granulation

The roller extrusion granulation method revolves around compressing raw materials into solid pellets without the need for external heat sources.

This is achieved through mechanical pressure, which binds the materials together. The process is advantageous for maintaining the nutritional integrity of the biofertilizer since excessive heat can degrade organic compounds, reducing their effectiveness.

Roller granulator working principle:

- Double Roller Extrusion: The roller extrusion granulator extrudes the material through two synchronized counter-rotating rollers. The material is added from the top of the machine and enters into the roller after degassing and screw pre-pressurization. Under the strong extrusion pressure of the rollers, the material is compressed into dense flakes.

- Pelletizing: The flakes are then crushed, pelletized and screened to form a uniform pelletized product. This process does not require the addition of water, binders or auxiliaries or subsequent drying.

Steps to Produce Biofertilizer Pellets

- Preparation of Raw Materials:

Begin by gathering the organic materials required for the biofertilizer. Common components include agricultural residues, animal manure, and compost. Ensure that these materials are uniformly mixed and have a consistent moisture content, typically between 20% to 30%, to facilitate molding.

- Feeding into the Granulator:

Once the raw mix is prepared, it is fed into the hopper of the roller extrusion granulator. The machine uses roller shafts to compress the materials into uniform shapes. The pressure applied during this stage is adjustable, allowing the operator to modify pellet density and diameter according to specific needs.

As the material passes between the rollers, it is subjected to high pressure, resulting in the creation of dense, uniform pellets. The roller design and gap adjustment are critical as they determine the size and quality of the final product. Click here to learn more specific methods.

- Screening and Quality Control:

After granulation, the pellets are screened to ensure consistent size and quality. Oversized or undersized pellets can be recycled back into the process. This stage guarantees that only appropriately sized pellets, between 3mm and 10mm, move forward for packaging and distribution.

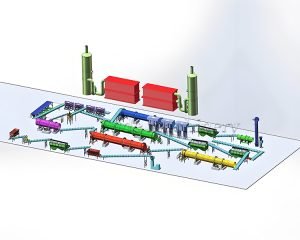

Fude Machinery not only provide you the high-quality double-roller extrusion granunlator,but offer you the complete extrusion granulation plant, welcome to consult!

Advantages of Roller Extrusion Granulation

- Energy Efficiency: The elimination of drying and cooling stages significantly reduces energy consumption.

- Nutrient Preservation: Low thermal impact preserves the organic matter and nutrient content of the biofertilizer.

- Economic Viability: Lower operational costs make this method attractive for large-scale production facilities focusing on sustainable agriculture.

Characteristics of Roller Pelletizer Machine:

- Normal temperature pelletizing: adopting non-drying normal temperature process, the product is extruded and molded at one time, reducing energy consumption and production cost.

- Adjustable pellet size: the pellet size can be adjusted through the mold, usually between 0.3-10 mm, to meet different production needs.

- High strength and wear-resistant: the roller skins are made of high-strength materials with good wear-resistant performance and long service life, and the materials can be customized according to different materials.

- Compact and efficient: the equipment is reasonably designed, compact structure, small footprint, suitable for large, medium and small production lines.

Roller granulator application areas:

- Multi-industry application: widely used in chemical fertilizer, medicine, chemical, feed, coal, metallurgy and other industries. Suitable for the production of various concentrations and types of compound fertilizer, organic fertilizer, bio-fertilizer and so on.

- Special material processing: It is especially suitable for the processing needs of special materials such as heat-sensitive materials, easily hygroscopic materials, etc. to ensure the purity of products.

By utilizing a roller extrusion granulator, producers can efficiently transform raw organic materials into high-quality biofertilizer pellets. The process not only supports sustainable agricultural practices but also aligns with the growing demand for environmentally-friendly fertilization solutions. As global emphasis on sustainable agriculture intensifies, mastering such production techniques becomes increasingly crucial within the agricultural sector.

Organic fertilizer equipment,organic fertilizer production line,organic fertilizer equipment factory

Organic fertilizer equipment,organic fertilizer production line,organic fertilizer equipment factory