In the organic fertilizer production sector, transforming composted organic fertilizers into fine powder products that meet market demands is a core step in enhancing product value.

As a company with years of expertise in organic fertilizer equipment, Fude Machinery combines industry practice and technical experience to systematically analyze the key equipment selection logic for producing fine powder from composted organic fertilizers. This provides industry users with a scientific basis for decision-making.

Pre-processing Stage: The Core Function of Crushing Equipment

Compost feedstock typically consists of organic waste such as livestock manure, crop straw, and fungal residues. These materials feature large initial particle sizes and wide moisture content fluctuations (25%-55%). Direct processing into fine powder often leads to equipment clogging and surging energy consumption. Consequently, semi-wet material pulverizers have become the core equipment in the pretreatment stage.

Technical Principles and Advantages

This equipment employs a chain-type crushing structure, utilizing high-speed rotating chain hammers to impact, shear, and grind materials. Its unique design achieves three major breakthroughs:

- High-Moisture Material Adaptability: Processes materials with moisture content ranging from 25% to 55%, preventing clogging issues caused by material adhesion in traditional equipment.

- Hard Material Processing Capability: Grinds impurities such as glass, ceramics, and bricks, ensuring final product safety.

- Precise particle size control: By adjusting hammer gap and rotational speed, materials can be crushed to a particle size of 0.5-5mm, meeting subsequent granulation or screening requirements.

Screening Process: Redefining the Value of Drum Screeners

The crushed material must pass through screening equipment to remove large impurities, ensuring the uniformity of the fine powder product. The drum screen, with its self-cleaning function and high-efficiency screening capability, is the preferred equipment for this process.

1.Technical Specifications Analysis

- Multi-stage screening capability: Utilizes a modular screen mesh design to achieve three-stage separation, simultaneously sorting finished products, return material, and impurities.

- Dynamic self-cleaning mechanism: Centrifugal force generated by drum rotation keeps the screen surface clean, preventing clogging.

- Flexible feeding methods: Supports both manual and mechanically driven feeding modes to accommodate production lines of varying scales.

2.Enhanced Production Efficiency

Taking Fude Machinery’s FD series drum screen as an example, it achieves a processing capacity of 1-10 tons per hour with screening precision meeting Class I standards.

In powdered organic fertilizer production lines, this equipment integrates with belt conveyors and automatic packaging machines to form a closed-loop production system, boosting the qualified product rate to over 98%.

Process Synergy: A Systematic Approach to Equipment Selection

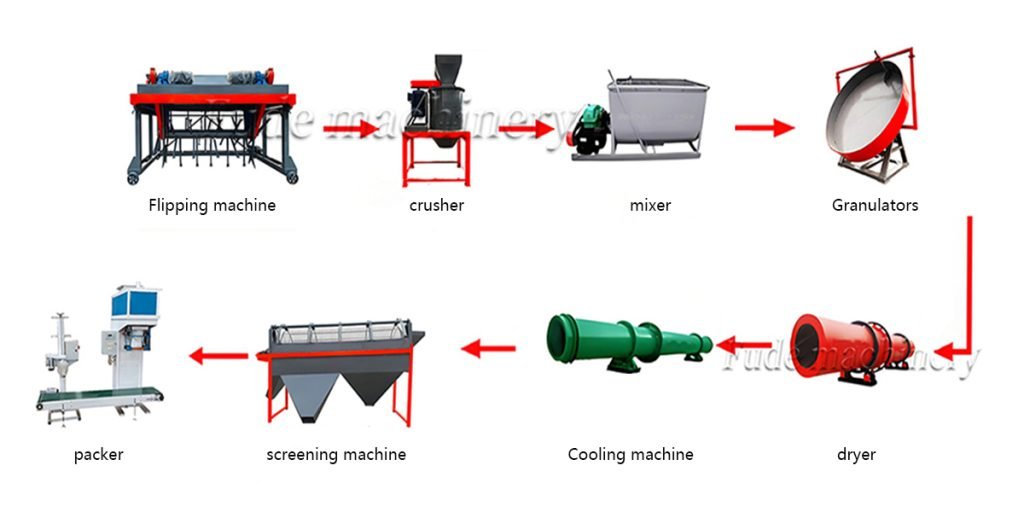

Organic fertilizer production is a complex system involving multiple stages such as fermentation, crushing, screening, and packaging. Equipment selection must adhere to three key principles:

1.Process Adaptability

Select equipment combinations based on raw material characteristics. For instance, when processing high-fiber materials like cattle manure, chain crushers should be prioritized. If raw materials have low moisture content, hammer crushers can be chosen to reduce energy consumption.

2.Production Capacity Matching

Equipment capacity must align with the overall scale of the production line. Fude Machinery offers modular equipment solutions ranging from 5 to 20 tons per hour, flexibly adapting to the needs of small family workshops and large fertilizer enterprises.

3.Maintenance Convenience

Select equipment with simple structures and easily replaceable wear parts. The modular screen design of drum screeners reduces single-screen replacement time to under 30 minutes, significantly minimizing downtime losses.

Industry Trends: Dual-Drive of Intelligence and Environmental Sustainability

As the organic fertilizer industry evolves toward precision and sustainability, equipment technology upgrades are showing two major trends:

1.Intelligent Control

Integrated PLC automatic control system enables real-time monitoring and adjustment of equipment operating parameters. For instance, sensors monitor current fluctuations in the crusher and automatically regulate feed rate to prevent equipment overload.

2.Environmental Performance Optimization

Features a fully enclosed structural design with a pulse dust removal system, ensuring dust emission concentrations below 10mg/m³ to meet environmental standards. Fude Machinery’s newly launched FD-Z series equipment has obtained CE certification for export to the EU market.

Conclusion

The transformation process from compost raw materials to fine powder products represents a deep integration of technological equipment and process innovation. With over a decade of industry experience, Fude Machinery has developed comprehensive equipment solutions covering the entire chain—from crushing and screening to granulation and packaging. When selecting equipment, we recommend users prioritize three key metrics: wet material processing capacity, screening precision, and maintenance costs. Scientific configuration maximizes production efficiency. Moving forward, Fude Machinery will continue to deepen its expertise in organic fertilizer equipment, driving green agricultural development through technological innovation.

Organic fertilizer equipment,organic fertilizer production line,organic fertilizer equipment factory

Organic fertilizer equipment,organic fertilizer production line,organic fertilizer equipment factory