Pet aquatic feed puffing machine

Feed expanding machine, also known as dog food machine, is a kind of mechanical equipment specially used for processing animal feed, it is through high temperature, high pressure, high shear and other physical effects, so that the feed raw materials in a short period of time to expand, ripening, structural changes and a series of changes, so as to produce puffed feed with special physical and chemical properties.

Feed puffer working principle

Feed puffer uses mechanical energy to feed raw materials (such as corn, soybean meal, fish meal, etc.) into the extrusion chamber, under the action of high temperature, high pressure and high-speed shear, the moisture in the raw material is rapidly vaporized to form steam bubbles, so that the material volume expansion.

When the material is extruded through the mold, the sudden drop in pressure causes the steam bubble to expand rapidly and rupture, forming a porous, loose puffed structure. At the same time, high temperature and high pressure conditions can destroy the anti-nutritional factors in the raw materials, improve protein digestibility, and kill harmful microorganisms, prolong the shelf life of feed.

The core function and composition of the dog food machine

core functionality

- Raw material processing: Mixing of powders (e.g. corn meal, fish meal, fresh meat puree, etc.) and enhancement of raw material homogeneity and plasticity through tempering.

- Extruding and puffing: apply high temperature, high pressure and mechanical shear to the materials by using single/twin-screw extruder to make starch pasty, protein denaturation and formation of porous structure.

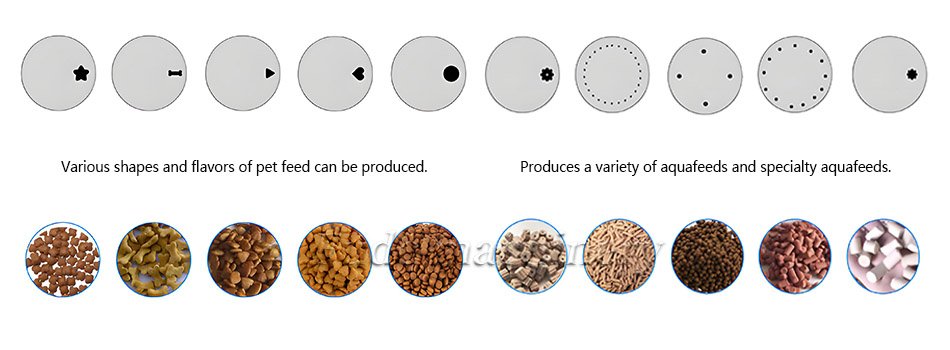

- Forming & Drying: Cut into different shapes (round, bone, etc.) through molds, then remove moisture through multi-layer ovens or continuous drying ovens to extend shelf life.

- Flavoring & Packaging: Sprayed with oil, vitamins or flavor agents and automatically packaged after screening through vibrating screen

Main components

- Feeding system: The raw material is fed evenly into the puffing chamber by means of a screw conveyor.

- Expansion Chamber: The core component, containing the screw shaft, extrusion die and heating/cooling unit, generates high temperature and pressure through friction and shearing.

- Cutting system: cuts the expanded material from the extrusion die into defined lengths (e.g. pellets, strips or flakes).

- Driving system: motor and reducer provide power, speed adjustable to suit different raw materials.

- Control system: adjust temperature, pressure, speed and other parameters to ensure process stability.n

Classification and technical characteristics

According to the processing technology and use, feed puffer can be divided into the following types:

- Dry puffer: no steam tempering, direct extrusion puffing, suitable for high fat and high protein raw materials (such as pet food).

- Wet extruder: raw materials enter into the expansion chamber after steam tempering, low energy consumption, suitable for aquatic feed.

- Single screw extruder: simple structure, low cost, suitable for small and medium-sized feed mills.

- Twin-screw extruder: even mixing, precise temperature control, suitable for high value-added feeds (e.g. preterm baby milk powder base material).

Characteristics of expanded feed

- Improved digestibility: starch pasting degree reaches more than 90%, protein denaturation, easier to be absorbed by animals.

- Improvement of palatability: porous structure increases surface area, flavor release, attracting animals to feed.

- Bactericidal and insecticidal: High-temperature treatment can kill pathogens such as Salmonella and E. coli, reducing the risk of mold and mildew in feed.

- Extended shelf life: low moisture (10%-12%) and sealed packaging can be stored for 6-12 months.

- Wide adaptability of raw materials: can process grains, beans, fish meal, algae, etc., and even add drugs or probiotics.

Application Scenarios for Dog Food Machines

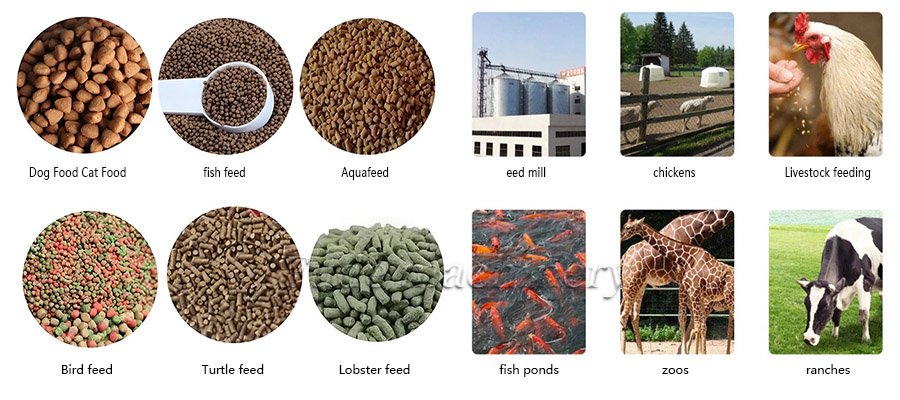

- Aquaculture: puffed floating feed (such as bass, tilapia feed) can reduce water pollution and improve utilization.

- Pet food: the puffing process gives pet food a crispy texture and adds nutrients more evenly.

- Livestock breeding: young animals (such as piglets, calves) need high digestibility of feed, puffing process can reduce the rate of diarrhea.

- Specialty feeds: such as ornamental fish, turtles and soft-shelled turtles need customized shape and density of puffed feed.

Dog food machine development trend

- Intelligent control: real-time adjustment of process parameters through sensors and algorithms to improve product consistency.

- Energy saving and environmental protection: reduce energy consumption by adopting waste heat recovery, frequency conversion motor and other technologies.

- Multifunctionalization: develop integrated equipment for simultaneous production of puffing, granulation and coating.

- Customized demand: design special models for special farming (such as insect protein feed).

As the core equipment of modern feed industry, feed puffer, its technological progress directly promote the efficient and safe development of the breeding industry.

Organic fertilizer equipment,organic fertilizer production line,organic fertilizer equipment factory

Organic fertilizer equipment,organic fertilizer production line,organic fertilizer equipment factory