What Advantages Do Double Roller Extruders Offer in Lime Fertilizer Pellet Making?

195In contemporary agriculture, the production of high-quality fertilizers is essential for enhancing soil fertility and boosting crop yields.

View detailsSearch the whole station

As a manufacturer of fertilizer production equipment, we are well aware of agriculture’s need for efficient fertilizers and are committed to providing the best ammonium sulfate pellet production line to meet the market demand for quality fertilizers. As a nitrogen fertilizer, ammonium sulfate not only provides essential nitrogen to plants, but also contains sulfur, which is vital to the growth of many crops. Our ammonium sulfate pellet production line adopts advanced technology and innovative design to ensure uniform pellet size, good hardness, and good solubility, which makes our products stand out in the market.

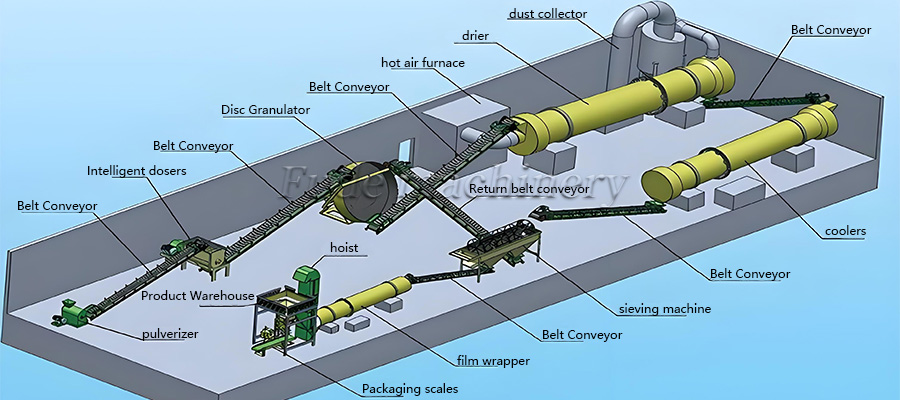

Ammonium sulfate pellet production line process mainly has two typical processes. Ammoniacal method of production, concentrated sulfuric acid and water in proportion to the proportion of dilute acid, and liquid ammonia after metering added to the tube reactor, while adding granulation tail gas scrubbing liquid reaction to generate ammonium sulfate slurry, slurry in the granulator and a variety of raw materials agglomerated into particles, after two drying, two-stage Vernier tube treatment of dust sieving, large particles into the chain mill, fine powder back to the granulator, after cooling and then fine sieve, fine powder back to the granulator, fine sieve particles after the film coating Moisture-proof into finished products; ammonia-containing tail gas treatment by-product process, the wet process of phosphoric acid slurry and sulfuric acid, tail wash solution with mixed acid, gas ammonia and other neutralization of ammonium sulfate slurry, sent to the granulator granulation drying, large particles of crushed or directly into the masterbatch, after sieving 2 – 4.5mm finished products after processing and packaging, sieving of exhaust water recycling scrubber, scrubber water with sulfuric acid to dilute sulfuric acid to scrub ammonia-containing tail gas tail wash solution used for mixing acid.

Ammonium sulfate pellet production line has significant advantages: product, high purity can accurately supply nitrogen, uniform particle size is conducive to the balanced distribution of nutrients, good stability to adapt to the storage and transportation; production, high degree of automation to reduce the degree of human intervention, large production capacity and short cycle, can efficiently meet market demand; application, easy to store and transport, mobility is good for a variety of equipment to accurately fertilization; environmental protection, dust removal equipment to reduce dust pollution, waste water recycling to reduce emissions; economic, reduce the cost of labor and energy consumption and other costs, but also to enhance the competitiveness of customized production. Environmental protection, dust removal equipment to reduce dust pollution, wastewater recycling to reduce emissions; economic, reduce labor, energy consumption and other costs, high value-added granular products, but also customized production, to enhance market competitiveness.

Agriculture: Ammonium sulfate granules are a high-quality nitrogen fertilizer, widely used in the cultivation of various crops. Ammonium sulfate granules are easy to store, transport and apply, and can provide stable nitrogen nutrition for crops and promote the growth and development of crops.

Industrial field: Ammonium sulfate granules are also used in textile, leather, medicine and other industries. For example, in the textile industry, ammonium sulfate can be used as a dyeing auxiliary; in the leather industry, it can be used as an additive in the tanning process.

In short, our ammonium sulfate pellet production line reflects our relentless pursuit of product quality and customer serviceWe are committed to providing the best fertilizer solutions for global agriculture, helping farmers to increase their yields and incomesBy choosing our ammonium sulfate pellet production line, you will be investing in a reliable, efficient and environmentally friendly production process that will lead to the long-term success of your fertilizer business. For more information, please contact us at Fuder Machinery!

In contemporary agriculture, the production of high-quality fertilizers is essential for enhancing soil fertility and boosting crop yields.

View detailsIn the realm of organic agriculture, carbon-based fertilizers have emerged as a key component for enhancing soil fertility and crop yield.

View detailsThe disc pelletizer is a core piece of equipment for making organic fertilizer pellets.

View detailsCow manure is a highly beneficial organic material that can be transformed into a nutrient-rich bio fertilizer.

View details