Processing pomace, a high-moisture organic waste, into organic fertilizer presents significant opportunities for industries like wineries, cider mills, and juicing facilities. Converting this byproduct not only addresses waste disposal challenges but also contributes to sustainable agriculture by producing valuable organic fertilizers.

Understanding the essential machinery involved in this transformation is crucial for efficient and effective fertilizer production from pomace.

Table of Contents

What Raw Materials Are Suitable for Organic Fertilizer Production from Pomace?

Pomace, the residual pulp after extracting juice from fruits such as apples, grapes, and berries, is rich in organic matter but contains over 90% moisture. This high moisture content makes direct use as fertilizer impractical. However, by processing pomace into organic fertilizer granules or pellets, industries can create a valuable product.

Other suitable raw materials include vegetable residues, brewery spent grains, and food processing waste. Utilizing these high-moisture organic wastes not only reduces environmental impact but also promotes sustainable waste management practices across various sectors.

Which Machines Are Essential in the Water Reduction Process of Pomace?

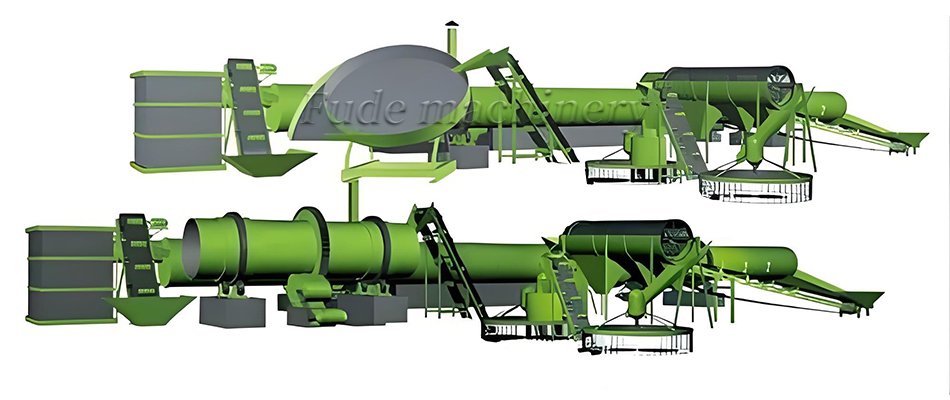

Reducing the moisture content of pomace is critical for producing stable and high-quality organic fertilizers. The water reduction process typically involves four stages to decrease moisture from over 90% to less than 10%. First, a dewatering machine or dehydrator mechanically removes excess water.

Next, composting equipment facilitates the natural decomposition process, further lowering moisture while enriching the material. Wet granulating machines, such as granulators or pelletizers, then transform the composted material into granules or pellets.

Finally, a pomace dryer plays a pivotal role by thoroughly drying the granules or pellets, achieving the desired moisture content for optimal storage and use.

What Are the Benefits of Using a Pomace Dryer in Organic Fertilizer Production?

The pomace dryer is essential in the moisture reduction process, ensuring that the final organic fertilizer product is of high quality. By efficiently removing residual moisture, the dryer enhances the durability and shelf life of fertilizer granules or pellets.

This machinery employs advanced drying technology to achieve uniform drying without compromising the nutritional value of the organic fertilizer. Using a pomace dryer not only streamlines the production process but also reduces energy consumption and operational costs.

Therefore, investing in a reliable pomace drying system is crucial for manufacturers aiming to produce superior organic fertilizers from pomace.

Blended NPK Fertilizer Production System: A Simple, Cost-Effective Process

Blended NPK fertilizers are an essential tool in modern agriculture, providing balanced nutrition for crops by combining the key nutrients nitrogen (N), phosphorus (P), and potassium (K) in precise ratios. These fertilizers are particularly favored for their simplicity in production, cost-effectiveness, and ability to enhance crop yield and soil health.

The process for producing blended NPK fertilizers is straightforward, making it an economical choice for farmers and fertilizer manufacturers alike.

In summary, processing pomace into organic fertilizer requires a series of specialized machines to effectively reduce moisture and enhance product quality. Essential machinery includes dewatering equipment, composting systems, wet granulators or pelletizers, and most importantly, pomace dryers.

These machines collectively enable industries to convert high-moisture organic wastes into valuable fertilizer granules or pellets. By adopting this technology, industries can promote sustainable practices and contribute to environmental conservation. Partnering with a professional drying equipment manufacturer like Fude Machinery can provide tailored solutions to optimize the organic fertilizer production process from pomace.

Selection of Raw Materials

- The production of blended NPK fertilizers begins with the selection of the appropriate raw materials. It mixs N, P, K granules to produce fertilizer. The three main nutrient sources are:

- – Nitrogen (N) Granules: Nitrogen is a critical nutrient that promotes plant growth and helps in the formation of chlorophyll. Common nitrogen sources include ammonium nitrate, urea, and ammonium sulfate. These nitrogen-rich materials are readily available and are often in granule form for easy handling.

- – Phosphorus (P) Granules: Phosphorus is vital for root development, energy transfer, and flower formation. Phosphatic sources, such as single superphosphate (SSP) and triple superphosphate (TSP), are commonly used. These materials are often available in granular form, making them easy to mix and apply.

- – Potassium (K) Granules: Potassium supports disease resistance and photosynthesis. Muriate of potash (KCl) and potassium sulfate are common potassium sources, and these too are typically available as granules, making them convenient to incorporate into the fertilizer blend.

Weighing and Blending

Once the raw materials are selected, they are carefully weighed to achieve the desired nutrient ratio. For instance, a 15-15-15 NPK blend fertilizer making would consist of 15% nitrogen, 15% phosphorus, and 15% potassium. The specific ratio will depend on the crop’s nutrient requirements and soil conditions.

The raw materials are then mixed in a blending unit, such as a BB fertilizer mixer or a rotary drum mixer, to ensure a uniform distribution of the nutrients. The goal is to create a consistent blend, where each granule contains the right proportion of nitrogen, phosphorus, and potassium. More details.

Quality Control and Packaging

Once the materials are blended, the product undergoes quality control checks to ensure that the nutrient content matches the specified formulation and that the granules are free from contaminants. After passing quality tests, the blended NPK fertilizer is packaged in bags or bulk containers for distribution.

The production of blended NPK fertilizers is a simple and cost-effective process that combines nitrogen, phosphorus, and potassium granules in precise amounts. By choosing the right raw materials and following an efficient blending process, manufacturers can create high-quality fertilizers that support sustainable agriculture and improve crop yields. The straightforward production method and affordable price point make blended NPK fertilizers a popular choice among farmers worldwide.

Organic fertilizer equipment,organic fertilizer production line,organic fertilizer equipment factory

Organic fertilizer equipment,organic fertilizer production line,organic fertilizer equipment factory