What is the role of Bentonite Granules Making Machine?

Bentonite granules, often used in organic fertilizers, improve soil structure, increase water retention, and promote overall plant health. When processing bentonite rocks, a Bentonite Granules Making Machine is essential.

In this article, we explore the features, benefits, and applications of these machines, along with their role in enhancing fertilizer production.

Table of Contents

This machine typically includes several key components:

– Rotary Drum Granulator or Disc Pelletizer: These components help in the shaping and uniform size of the granules.

– Mixer: This helps in evenly blending the raw materials to ensure consistency in the final product.

– Dryer: After granulation, the bentonite granules are dried to remove excess moisture, ensuring they have the right texture and durability.

The entire process is automated, making it efficient and cost-effective for large-scale production. Learn more.

Benefits of Bentonite Granules Making Machine

- 1. High-Quality Granules: The primary advantage of using a Bentonite Granules Making Machine is its ability to produce high-quality, uniform granules. The granules help bind the fertilizer components, ensuring a slow and controlled release of nutrients to the plants. Or use bentonite granules as cat litter

- 2. Improved Soil Health: Bentonite, as a key ingredient in organic fertilizers, is known for its ability to improve soil quality. The granules help in increasing soil fertility, retaining moisture, and enhancing microbial activity. Using bentonite in granule form ensures these benefits are efficiently delivered.

- 3. Cost-Effective Production: The machine is designed to be highly efficient, minimizing waste and optimizing raw material usage. With an investment in a bentonite granules making machine, manufacturers can increase production output without significantly increasing labor or operational costs.

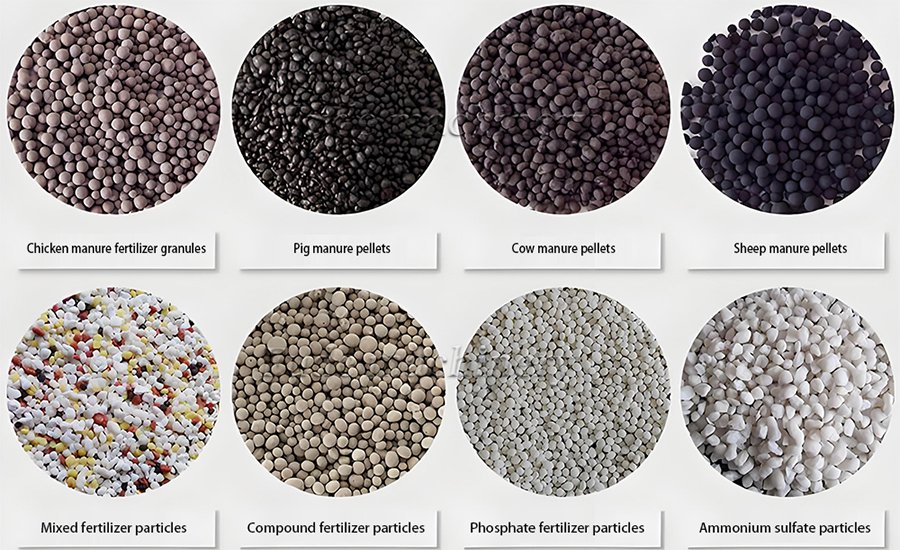

- 4. Versatility: The machine can be used to produce different types of granules, such as those mixed with other organic materials or purely bentonite-based. This flexibility makes it a valuable asset for businesses involved in organic and chemical fertilizer production.

Applications of Bentonite Granules in Fertilizer Production

Bentonite granules are widely used in the production of organic fertilizers. Their unique properties make them ideal for promoting soil health, improving water retention, and increasing nutrient availability for plants. Additionally, they are often mixed with other organic matter, such as compost, to create high-performance fertilizers.

The granules are also beneficial for improving the structural integrity of the fertilizer, ensuring that it can withstand handling and transportation without breaking apart.

Bentonite granulator equipment features

- High efficiency: the bentonite granulator can produce granules quickly and continuously to improve production efficiency.

- High granulation rate: through the optimization of design and process parameters, the granulation rate of the granulator can reach more than 90%.

- Uniformity of particles: the equipment can control the size and shape of the particles to ensure product consistency.

- Easy to operate: high degree of automation, simple operation, reduce manual intervention.

- Strong adaptability: it can be applied to bentonite raw materials with different particle sizes and moisture contents.

Bentonite granulator application areas

- Agriculture: bentonite particles can be used as a soil conditioner to improve soil water retention and permeability.

- Chemical: as drilling mud raw materials, adsorbents, etc., bentonite particles are widely used in the chemical industry.

- Building materials: used in the manufacture of lightweight building materials, sound insulation materials.

- Environmental protection: bentonite particles can be used for sewage treatment, exhaust gas treatment and other environmental protection areas.

- Pet supplies: bentonite cat litter is one of the important applications of bentonite particles.

Bentonite granulator is a specialized equipment for processing bentonite raw material into granular products, widely used in agriculture, chemical industry, building materials, environmental protection and other fields.

Bentonite is used as soil conditioner, drilling mud raw material, cat litter, adsorbent and so on because of its good adsorption, expansion, bonding and other properties, and the granulation process can improve its use efficiency and convenience.

Bentonite granulator selection recommendations

In the selection of bentonite granulator, the following factors need to be considered:

- Production scale: according to the production requirements to choose the appropriate equipment type and capacity.

- Particle requirements: according to the particle size, shape, strength and other requirements of the particles to choose the appropriate granulation.

- Raw material characteristics: consider the characteristics of bentonite particle size, moisture content, bonding, etc., select adaptable equipment.

- Budget: according to the investment budget to choose cost-effective equipment.

A Bentonite Granules Making Machine is an indispensable tool for businesses looking to produce high-quality, environmentally friendly organic fertilizers. By leveraging the unique properties of bentonite, manufacturers can offer fertilizers that enhance soil fertility and support sustainable agricultural practices.

With its efficiency, cost-effectiveness, and versatility, this machine is a smart investment for anyone in the fertilizer production industry. If you are interested in the project, you can visit We, Fude Machinery.

Organic fertilizer equipment,organic fertilizer production line,organic fertilizer equipment factory

Organic fertilizer equipment,organic fertilizer production line,organic fertilizer equipment factory