How to Granulate Mushroom and Medicine Dregs Successfully?

149A practical guide on granulating difficult materials like mushroom dregs and medicine dregs.

View detailsSearch the whole station

I am often asked about NPK production lines. An NPK production line is a complete system. It makes compound fertilizers. These fertilizers contain nitrogen (N), phosphorus (P), and potassium (K). These are essential nutrients for plant growth. This line processes raw materials into granular or powdered NPK fertilizers. It helps you create high-quality products for your farm or business.

Last updated: 2025年6月 | Estimated reading time: 8 minutes

This article will help you understand:

A compound fertilizer production line is a system for mixing multiple nutrients. It takes different raw materials. These materials contain nitrogen, phosphorus, and potassium. It then combines them into one finished fertilizer product. This process gives plants a balanced diet from one application. My company, Fude Machinery, specializes in similar fertilizer processing lines. We help businesses like yours create efficient production systems.

Compound fertilizers are different from single-nutrient fertilizers. They offer all three main plant nutrients in each granule. This makes them very efficient for farmers. It ensures plants get what they need for strong growth. This kind of line helps you produce a specific nutrient ratio. You can tailor it to different crop needs and soil types. Our equipment supports precise mixing for these formulations.

NPK stands for Nitrogen (N), Phosphorus (P), and Potassium (K). These are the three primary macronutrients. Plants need them in large amounts. Nitrogen helps with leafy growth. It makes plants green and strong. Phosphorus supports root development and flowering. It is vital for fruit and seed production. Potassium boosts overall plant health. It helps with water use and disease resistance.

Practical tips for your NPK production:

Real-world example: A large agricultural cooperative needed a specific 15-15-15 NPK fertilizer. We helped them design a line. It precisely mixed urea, DAP, and MOP. The final product consistently met their quality standards.

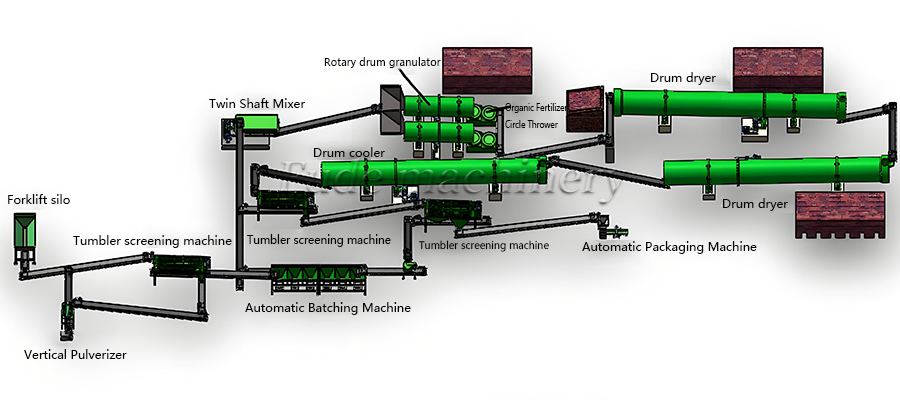

Making NPK fertilizer involves several important steps. Each stage uses specific equipment. These steps ensure a high-quality finished product. I focus on providing reliable machines for each stage. This helps your operation run smoothly and efficiently.

The first step is preparing your raw materials. You weigh each raw material precisely. This includes nitrogen, phosphorus, and potassium sources. You also add any fillers or binders. Accurate weighing ensures the final NPK ratio is correct. After weighing, all materials go into a mixer. A mixing/blending system ensures thorough blending. This creates a homogeneous mixture before granulation.

Granulation is the core of NPK production. This is where the mixed raw materials form into granules. There are different methods. My company offers various granulating systems . Common choices include disc granulators, rotary drum granulators, and roller granulators. Each has benefits depending on your material and desired granule type.

A disc granulator forms granules through rotation. Material rolls on a tilted disc. Water or binders are added. This forms small, round pellets. A roller granulator presses material between two rollers. This creates compact granules. We also have compound fertilizer granulators specifically for NPK. The choice depends on your specific raw materials and production capacity needs. This stage is key for creating easy-to-spread fertilizer.

After granulation, the granules are usually wet. They contain too much moisture. The drying process removes this excess water. A drying/cooling machine is used. It rotates as hot air passes through. This reduces the moisture content to a safe level for storage. Proper drying prevents the granules from caking. It also stops them from breaking down.

After drying, the hot granules need cooling. A cooling machine brings their temperature down. This stops them from absorbing moisture from the air. Cooling also makes them harder. This helps them resist crushing during handling and transport. Both drying and cooling are vital for stable product quality. They ensure your fertilizer remains effective.

The last main steps are screening and packaging. A screening system separates the granules. It removes oversized and undersized particles. Only the correctly sized granules pass through. These are your finished products. The off-spec granules can be recycled. They return to the crushing or granulation stage. This minimizes waste.

Finally, the finished granules move to the packaging section. An automatic packaging system weighs and bags the fertilizer. This ensures accurate product weight. It prepares the fertilizer for shipping and sale. Automated packaging makes the process fast and efficient. It also reduces labor costs for your organic fertilizer producers or large farms.

Investing in an NPK production line offers many benefits. It is a strategic move for fertilizer manufacturers and large agricultural businesses. I help clients understand these advantages. They can improve their operations and profit from them.

The demand for balanced fertilizers is growing. Farmers want to optimize crop yields. They need specific NPK ratios for different crops. An NPK production line allows you to meet diverse market needs. You can produce a wide range of NPK formulas. This makes your product line versatile. It helps you cater to various agricultural segments. You can respond quickly to new market trends. This includes the growing interest in organic-inorganic compound fertilizers.

This flexibility makes your business more competitive. You can offer custom solutions. For example, a large farm might need a high phosphorus blend for root crops. Another might need a nitrogen-rich mix for leafy greens. Your NPK line lets you produce both. This expanded product range can increase your sales and market share.

Producing your own NPK fertilizer can save you money. You control the entire process from raw material to finished product. This reduces reliance on external suppliers for finished goods. You can buy raw materials in bulk. This often leads to lower costs. It also gives you full control over product quality. You ensure every batch meets your standards.

My equipment is designed for high efficiency and energy saving. This lowers your operational costs. We focus on durable machines. They reduce maintenance needs. This means less downtime and higher productivity. You can monitor each stage. This helps maintain consistent quality. It also minimizes waste. This combination of cost savings and quality assurance is a major advantage.

One significant benefit is customization. You can design fertilizers for specific soil types. You can also tailor them for particular crops. Farmers often face unique soil conditions. They might have nutrient deficiencies. An NPK production line lets you adjust the NPK ratio. You can also add trace elements. These might include magnesium, sulfur, or zinc.

This ability to customize makes your product highly valuable. It offers a precise solution to farmers’ needs. For instance, a coffee farm in a certain region might need a specific NPK with added boron. Your line can produce this. This level of customization sets you apart. It provides a unique selling proposition in the market.

The fertilizer industry is always evolving. New technologies make NPK production more efficient and sustainable. I follow these trends closely. I make sure our equipment incorporates the latest innovations.

Automation is a big trend in NPK production. Modern lines use advanced sensors and control systems. These systems monitor every stage. They adjust parameters automatically. This reduces the need for human intervention. It also increases precision. For example, intelligent systems can control the feeding rate of raw materials. They can also adjust granulator speed. This ensures consistent granule size and quality.

Sustainability is critical in 2025. NPK production lines are becoming more eco-friendly. There is a growing focus on energy efficiency. New designs reduce energy consumption. For example, our drying/cooling machines are designed to be energy-saving. They use heat recovery systems. This reduces fuel use.

Question 1: How much space does an NPK production line need?

An NPK production line needs varying space. It depends on your desired capacity and equipment type. A typical line might need a workshop of 8000 square meters. You should consider space for raw material storage and finished product storage.

Question 2: Can an NPK line produce organic-inorganic compound fertilizers?

Yes, an NPK line can produce organic-inorganic compound fertilizers. You can mix organic materials like composted manure with inorganic NPK ingredients. This creates a versatile product. Our machines, including the mixers and granulators, handle various material types.

Question 3: What is the typical lifespan of NPK production equipment?

The lifespan of NPK production equipment is usually long. It depends on maintenance and usage. Our machines are built with durable materials. They can last 10-15 years or more with proper care. Regular maintenance is important for longevity.

Question 4: Do you offer installation and training services?

Yes, I offer full-service support. This includes installation guidance and personnel training. My team of experienced engineers helps you set up the line. We also train your operators. This ensures smooth operation from day one.

An NPK production line is a comprehensive system. It transforms raw materials into high-quality compound fertilizers. I have explained its key stages. These include preparation, granulation, drying, screening, and packaging. Investing in such a line offers many benefits. You can meet diverse market demands. You gain cost efficiency. You also control product quality. Plus, you can customize fertilizers for specific needs.

I recommend you assess your specific needs first. Consider your desired production capacity. Think about your raw material types. Also, determine the NPK ratios you want to produce. This will help you choose the right equipment and line design. My team can help you with this assessment.

I represent Fude Machinery, a leading Chinese organic fertilizer equipment manufacturer. We are based in Zhengzhou. Our company specializes in B2B solutions. We provide a full range of organic fertilizer equipment. This includes composting machines , crushers, granulators, and complete production lines. We serve organic fertilizer producers, large farms, chemical material granulation plants, and distributors worldwide. Our factory covers 8000 square meters. We produce over 500 units annually. Our 15-member R&D team ensures top-quality design and products. We have exported to over 120 countries.

Contact me today to discuss your NPK production line needs. We can design a customized solution for you.

Last updated: 2025年6月

A practical guide on granulating difficult materials like mushroom dregs and medicine dregs.

View detailsIn the pursuit of sustainable agriculture, composting hog manure is a practical and environmentally friendly solution.

View detailshey have different diameters, different motor powers, and different capacity ratings.

View detailsA guide for cattle farms on treating manure with coarse fibers.

View details