What are the uses of organic fertilizer double shaft mixer

276Organic fertilizer double shaft mixer is mainly used to thoroughly mix organic fertilizer raw materials to ensure the quality of organic fertilizer

View detailsSearch the whole station

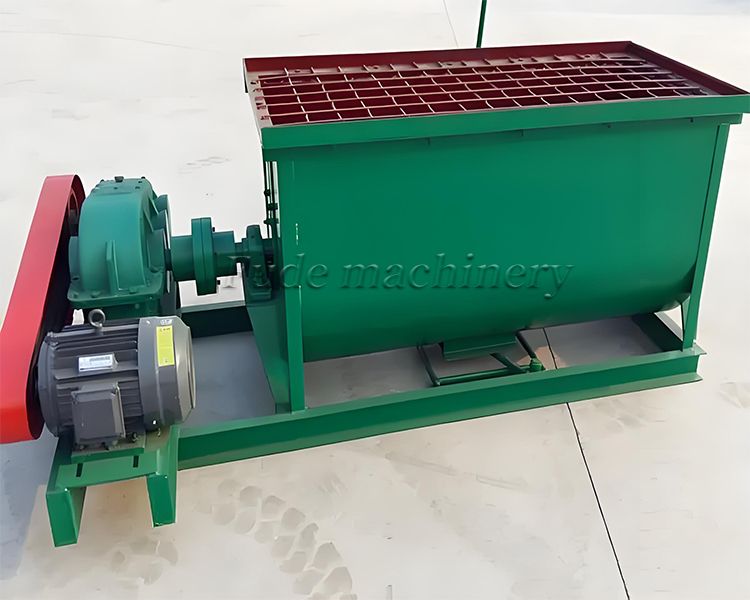

Organic fertilizer horizontal mixers have a wide range of applications in organic fertilizer production and related fields.

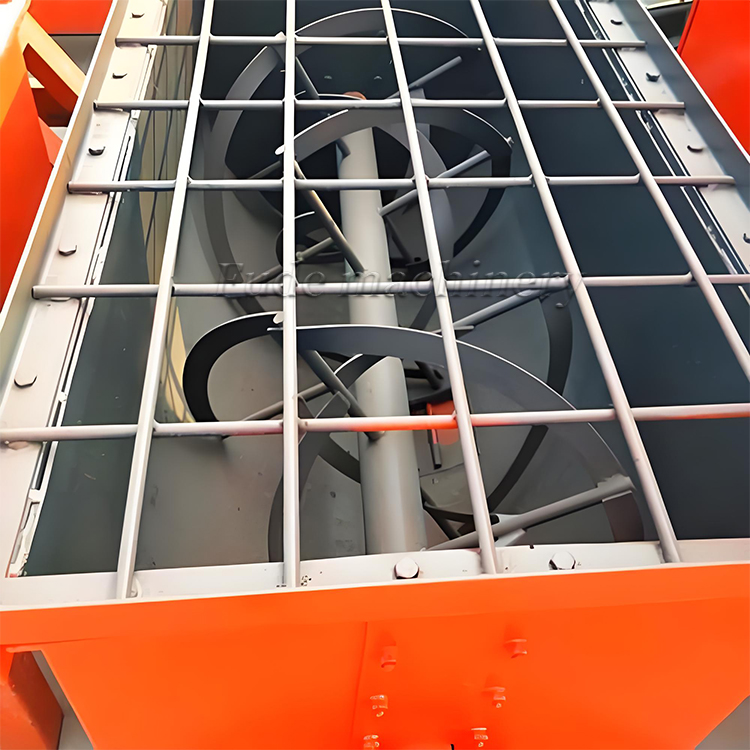

Spiral mixing shaft

Mixing organic raw materials: The organic fertilizer horizontal mixer is mainly used to mix various organic raw materials, such as chicken manure, cow manure, pig manure, straw, leaves, etc. Through efficient mixing process, high-quality organic fertilizers are produced to provide sufficient nutrients for crops, thereby improving crop yield and quality.

Improve production efficiency: The equipment is driven by a motor, with fast mixing speed, which can mix the raw materials evenly in a short time, thereby improving production efficiency. At the same time, some models such as large horizontal powder mixers for automatic feeding of organic fertilizers also have an automatic feeding system, further reducing manual operations and improving the automation level of the production line.

Configure a safety net

The single shaft is fitted with specially designed spiral ribbons or paddles that continuously scoop, lift, and tumble the material from one end of the mixer to the other. This constant motion guarantees a thorough and uniform blend.

Even though the design is simple, the mixing action is very effective. The key is the design of the paddles on the central shaft.

This process guarantees a consistent, homogeneous mix every time, which is essential for producing high-quality fertilizer that your customers can trust.

| model | Specification (mm) | Speed (r/min) | Power (kw) | Output (t/h) |

| WJ-600 | 600*1200 | 45 | 5.5 | 1.5-2 |

| WJ-700 | 700*1500 | 45 | 7.5 | 2-3 |

| WJ-900 | 900*1500 | 45 | 11 | 3-5 |

| WJ-1000 | 1000*2000 | 50 | 15 | 5-8 |

Horizontal mixer sent to the United States

Horizontal mixer sent to France

Question 1: What is the capacity of this horizontal fertilizer mixer?

We offer a full range of standard sizes, typically from 500 kg to 5,000 kg capacity per batch. As a manufacturer, we can also design and build a custom size to perfectly match the needs of your complete fertilizer production line .

Question 2: How long does a typical mixing cycle take?

For most dry fertilizer materials, a thorough and uniform mix is achieved in just 5 to 10 minutes. The exact time can vary slightly depending on the density and properties of your specific raw materials.

Question 3: Can I add a small amount of liquid?

Yes, a small amount of liquid, like water, can be sprayed in to control dust or slightly increase moisture. However, this mixer is not designed for adding large volumes of liquid. If your formula requires a lot of liquid, our Twin-Shaft Mixer is a better choice.

Question 4: What is the difference between a ribbon and a paddle rotor?

A ribbon rotor uses long, continuous spiral blades and is excellent for blending materials of similar size and density, like in BB fertilizer. A paddle rotor uses individual, angled paddles and provides a slightly more aggressive mixing action, which can be better for materials that are a bit more difficult to blend. We will help you choose the right type for your application.

Yes, this mixer is extremely versatile and is an excellent choice for blending dry powders, small granules, and is especially good for making BB (Bulk Blending) fertilizers.

The gentle yet thorough mixing action of the single-shaft Horizontal Fertilizer Mixer makes it perfect for a wide variety of applications in your plant.

The production equipment includes: fermentation raking machine, dryer, granulator, crusher, mixer, round throwing machine, organic fertilizer production line, etc. The company will continue to adhere to the business philosophy of “quality first, customer first” and provide higher quality metal equipment solutions for global customers.

Since its establishment in 2015, Fude Machinery has been committed to providing high-quality and high-performance metal equipment solutions to global customers. With advanced production technology, strict quality control, and continuous innovative research and development capabilities, we have received customer satisfaction praise.

Organic fertilizer double shaft mixer is mainly used to thoroughly mix organic fertilizer raw materials to ensure the quality of organic fertilizer

View detailsDouble axis humidification mixer is a device specifically designed for material humidification and mixing

View detailsStacked screw solid-liquid separator is a practical solid-liquid separation equipment.

View detailsTrack flipper is an efficient, environmentally friendly, and multifunctional material handling equipment

View detailsRoller extrusion granulator is a kind of mechanical equipment that uses the principle of roller extrusion to directly press dry powder materials into granules, which is widely used in chemical fertilizer, chemical industry, feed and other industries.

View detailsSemi wet material crusher is a professional crushing equipment for high humidity and multi fiber materials

View details