Organic Fertilizer Granulators and Types

133Organic fertilizer granulator is a machine that converts organic waste materials such as animal manure into granules.

View detailsSearch the whole station

I often talk to people who want to start or improve their organic fertilizer business. They always ask about money. They want to know about production costs and equipment investment. These two things are very important for any organic fertilizer company. They directly affect how much profit you make. They also decide how well your company can grow. Understanding them is key. It helps you make smart decisions. I will explain what these terms mean for organic fertilizer companies. I will also tell you how they impact your business.

Last Updated: June 2025 | Estimated Reading Time: 15 minutes

This article will help you understand:

Production costs are all the expenses your company pays to make organic fertilizer. These costs are important. They determine your selling price. They also impact your profit margins. Understanding each cost helps you find ways to save money. We divide these costs into direct and indirect categories.

Direct costs in fertilizer production are expenses directly linked to making each unit. The major one is raw materials: organic fertilizer uses animal manure, crop straw, municipal sludge, or food waste, with costs varying by availability and quality (sometimes free, but often requiring payment for collection and transport). Labor costs cover managing fermentation, operating machines, and packaging. Energy costs are significant, encompassing electricity for machines and drying/cooling equipment, as well as fuel for transport. Consumables like water, granulation binders, and packaging bags also contribute to direct costs.

Indirect costs, though not tied to individual fertilizer units, are essential for business operations. They include maintenance costs for machine repairs and upkeep, quality control expenses to ensure product standards, administrative overhead like office salaries, rent, and utilities, transportation costs for delivering finished products, and marketing/sales expenses to promote the fertilizer. These indirect costs accumulate, adding to overall production expenses, and effective management is key to business health.

Several factors influence production costs. Raw material availability and quality are crucial; scarce or low-quality materials raise costs due to higher prices or increased processing needs. Operation scale matters too, as larger companies benefit from economies of scale, buying materials in bulk and operating machines efficiently to lower per-ton costs. Technology is another key factor, with modern, efficient machinery reducing energy and labor use while boosting output, thus lowering per-unit costs (e.g., advanced organic fertilizer equipment). Labor wages and energy prices also significantly impact costs, with increases in either raising overall expenses. Monitoring these factors aids in effective budget management.

Actual Case: A client in Africa faced high energy costs for drying. We suggested a system that uses waste heat from their primary fermenter. This reduced their drying energy costs by 25%. This shows how smart technology choices impact costs.

Equipment investment is the initial money you spend to buy all the machines needed to start or expand your organic fertilizer business. This is a significant upfront cost. But, it is necessary to produce fertilizer. Choosing the right equipment is vital. It affects your production quality. It also affects your efficiency. It helps you reach your production goals.

My company, Fude Machinery, specializes in providing this equipment. We offer a full range of machines. These machines cover every step of organic fertilizer production.

Fermentation/Composting Equipment

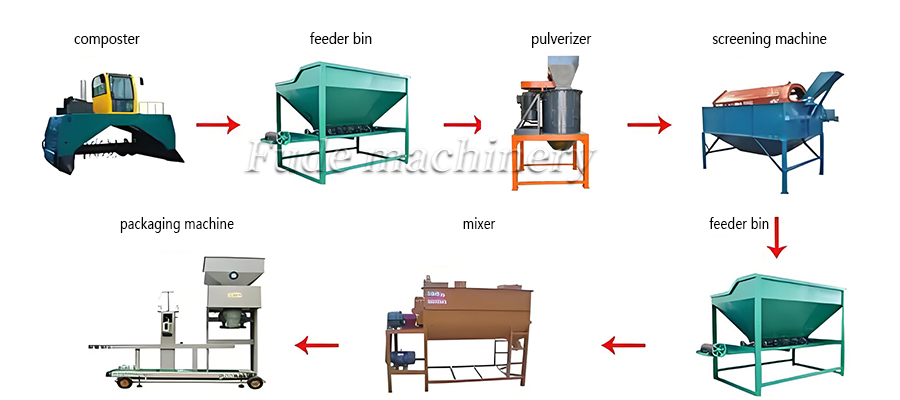

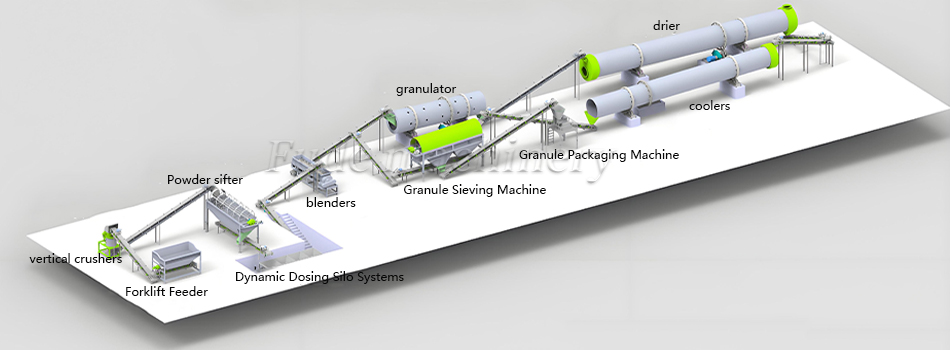

Compost turners are vital for preparing raw organic materials. Options include groove type (for fixed beds), crawler type (flexible for various sites), wheel disc (highly efficient), and chain plate (for deep fermentation). The right choice ensures efficient composting, the basis for quality fertilizer.

After fermentation, organic fertilizer crushers break down materials to a uniform size. We offer vertical, horizontal, and wet/dry material crushers. Proper crushing enhances granulation efficiency.

This is key for making granular fertilizer. Types include disc (round pellets), roller press (uses pressure), rotary drum (for large capacities), stirring tooth (mixes and granulates), and polishing machines (smoother pellets). The choice depends on material and product needs, crucial for quality.

Granules often need drying (rotary dryers) to reduce moisture, followed by cooling to ambient temperature to prevent caking and aid storage, ensuring product stability.

Screeners sort pellets by size, and automatic packaging machines weigh and bag the fertilizer accurately and efficiently, preparing it for market.

We can provide a full organic fertilizer production line, designing and supplying all interconnected machines from raw material entry to final packaging for a smooth, integrated process.

Choosing the right, high-quality, customizable equipment is essential. It’s more efficient, durable, requires less maintenance, reduces operational costs, and meets specific production needs. Our team helps select the best machines for an effective investment.

Production costs and equipment investment directly shape your organic fertilizer company’s future. They affect your ability to make money. They also impact your standing in the market. Understanding these implications helps you strategize better.

Profitability is directly affected. High production costs cut into profit margins per ton of fertilizer sold, potentially leading to losses. Efficient equipment slashes costs. Energy-saving dryers reduce electricity bills, and automated packaging machines cut labor needs, directly boosting profits. Smart equipment investments lower per-unit production costs over time, enhancing business profitability.

Market competitiveness is also influenced. Lower production costs enable more competitive pricing, attracting more customers. High-quality equipment ensures a superior product, like granulators producing uniform, strong pellets favored by customers. A company with lower costs and higher quality gains a competitive edge.

Scalability, or the ability to grow the business, is tied to initial equipment investment. Modular or expandable equipment makes it easier to add capacity later. A well-designed production line can handle increased demand, allowing for response to market growth. If the current setup can’t handle more volume, scaling up requires another large investment. Planning for scalability from the outset is wise.

ROI is a crucial financial measure. It indicates how long it takes for equipment investment to pay for itself through increased profits or cost savings. Efficient, reliable machines shorten the ROI period. For instance, a machine that reduces labor by two people may pay for itself in a few years, while a frequently breaking machine will have a poor ROI. Calculating ROI justifies initial investment.

Fude Machinery is well – aware of production challenges and designs organic fertilizer equipment and services to help you manage costs and investments effectively, benefiting your bottom line.

We offer a full range of machines, eliminating the need to source from multiple suppliers. This simplifies purchasing, ensures machine compatibility, and saves time and effort by guaranteeing system integration.

Recognizing that each client has distinct raw materials, output goals, and factory space, we tailor equipment and solutions. This avoids unnecessary features, optimizes investment, and provides exactly what’s needed for efficient operations.

Our machines are designed for efficient operation, consuming less power. Dryers use less fuel to remove moisture, and granulators achieve high output with minimal waste. This lowers per – ton production costs and boosts profitability.

We offer more than just machine sales. Our support covers initial solution design, equipment manufacturing, installation, debugging, staff training, and after – sales maintenance. This reduces hidden costs, minimizes downtime, and ensures smooth operations from the start, protecting your investment.

As a manufacturer, we sell directly to you, cutting out middlemen. This results in more competitive equipment prices, offering better value for your money and ensuring wise investment.

Since 2015, we’ve gained rich industry experience. Our 15 – member professional organic fertilizer engineering R&D team ensures high – quality design and production. You get reliable, proven equipment that reduces investment risks and is built to last.

The organic fertilizer industry is changing rapidly. Several trends in 2025 are affecting how companies manage their costs and investments. Staying aware of these trends helps you plan for the future.

Increased Automation: Automation is a big trend. More and more machines are becoming automatic. This reduces the need for manual labor. This directly lowers labor costs. Automated systems can also run 24/7. This increases efficiency. It also improves consistency. Investing in automation might mean a higher upfront cost. But, it often leads to significant long-term savings. It also increases your production capacity.

Latest Progress:

Growing Demand for Organic Products: The global market for organic fertilizer is expanding. This growth creates more opportunities for organic fertilizer companies. It justifies higher investments in specialized equipment. It also supports higher production volumes. This increased demand helps companies achieve economies of scale. This can drive down per-unit production costs.

These trends suggest that strategic investment in modern, efficient, and smart equipment is key. It helps you manage costs effectively. It also positions your company for success in a growing market.

Question 1: How can I reduce production costs for organic fertilizer?

You can reduce costs by optimizing raw material sourcing. Choose efficient, energy-saving equipment. Implement automation where possible. Conduct regular machine maintenance. This avoids costly breakdowns. Focus on efficient production processes.

Question 2: What is a typical investment for an organic fertilizer plant?

The investment varies greatly. It depends on your desired production capacity. It also depends on the level of automation. A small-scale plant might need hundreds of thousands of dollars. A large-scale, fully automated plant could require millions. It is best to get a detailed quote based on your specific needs.

Question 3: Does new equipment always mean lower production costs?

New equipment often leads to lower production costs. It is usually more energy-efficient. It often requires less labor. It also has higher output. However, you must choose the right equipment for your specific needs. A higher initial investment in quality equipment often yields significant long-term savings.

Understanding production costs and equipment investment is fundamental for any organic fertilizer company. Production costs include everything you spend to make fertilizer. This includes raw materials, labor, energy, and maintenance. Equipment investment is the initial capital outlay for machines. These two factors directly influence your company’s profitability, competitiveness, and ability to grow.

We are Fude Machinery, a leading Chinese manufacturer of organic fertilizer equipment. Our base is in Zhengzhou. We focus on B2B solutions. We offer a full range of organic fertilizer equipment. This covers composting, crushing, granulation, drying, cooling, and packaging. We also design complete production lines. Our facilities are well-equipped. We have strict quality control. We have exported our products to over 120 countries. Our team of 15 technical engineers ensures top-quality design and production for you.

Do you want to discuss your production costs or equipment investment needs? Are you ready to optimize your organic fertilizer operation? Contact our expert team today. We can help you find the most cost-effective and efficient solutions. We will help you succeed.

Last Updated: June 2025

Organic fertilizer granulator is a machine that converts organic waste materials such as animal manure into granules.

View detailsIn the production of mineral fertilizer pellets, granulation equipment plays a pivotal role in determining the final quality of the product.

View detailsIn practical application, our organic fertilizer disc granulator is highly adaptable and practical.

View detailsThis guide shows you how to turn biogas slurry and solids into valuable organic fertilizer pellets with the right equipment.

View details