With accelerating urbanization and population growth, the amount of sludge produced in wastewater treatment plants continues to increase. Efficient handling and utilization of this sludge is becoming an important challenge for governments and companies.

In this context, a production line for converting sludge into organic fertilizer has emerged as a promising solution, offering a resource-saving approach to sludge utilization.

Problems of sludge handling

Sludge, as a by-product of wastewater treatment, is rich in organic matter and nutrients, but can also contain heavy metals and pathogens. Traditional disposal methods such as landfilling and incineration are not only costly, but can also cause secondary pollution.

Therefore, finding an economical, efficient and environmentally friendly method of sludge utilization has become a necessity.

Advantages of organic sludge fertilizer

Sludge processing into organic fertilizer is a resource-saving method. This process, thanks to high-temperature composting technologies, can effectively destroy pathogenic microorganisms, reduce the activity of heavy metals, while preserving organic matter and nutrients of sludge.

Organic fertilizer from sludge can improve soil structure, increase its fertility, promote plant growth and has significant agricultural value.

Process of production line operation

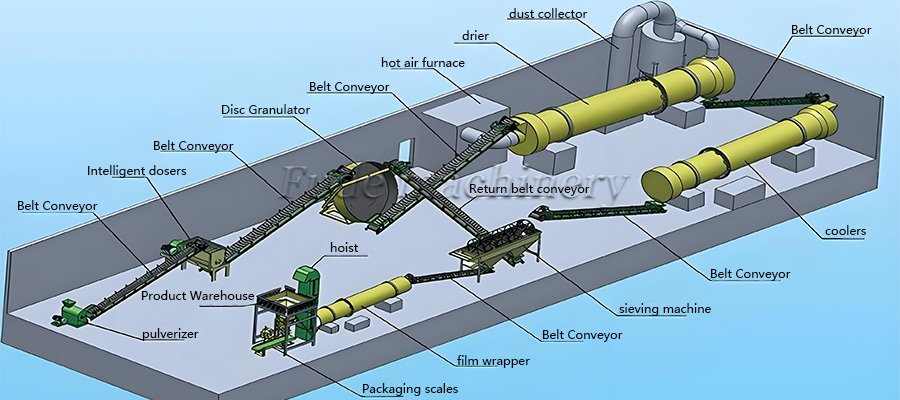

The production line for converting sludge into organic fertilizer includes several key steps: pre-treatment, blending, fermentation, drying, screening and packaging.

- Pretreatment: Sludge dewatering and initial treatment to reduce moisture content and remove coarse contaminants.

- Mixing: mixing the treated sludge with additives (such as straw, sawdust) in a certain proportion to increase the carbon-nitrogen ratio, which promotes fermentation.

- Fermentation: aerobic fermentation at high temperatures to decompose organic matter, kill pathogens and reduce heavy metal activity.

- Drying: additional reduction in the moisture content of the product for ease of storage and transportation.

- Screening: removal of not fully decomposed impurities, ensuring uniformity and quality of organic fertilizer.

- Packaging: packaging of the finished organic fertilizer for ease of sale and use.

Environmental and economic benefits

The production line for converting sludge into organic fertilizer not only makes efficient use of sludge and reduces environmental pollution, but also provides farmers with efficient and environmentally friendly fertilizer.

This circular economy model not only reduces the cost of sludge utilization, but also creates a new economic value chain. In addition, the construction and operation of the production line creates jobs and contributes to the local economy.

Future direction of development

With the development of technology and policy support, the processing of sludge into organic fertilizer has significant growth potential. In the future, production lines will be more focused on automation and intellectualization to improve productivity and product quality.

In addition, by strengthening cooperation with the agricultural sector, it is possible to expand the application of organic fertilizer and promote sustainable agricultural development.

Working principle of sludge fertilizer production line

The working principle of sludge fertilizer production line is that the collected sludge is firstly pre-treated to remove the large particles of impurities, stones, etc.,

And then the water content of the sludge is reduced by the dewatering equipment to meet the requirements of the subsequent treatment; then the pre-treated sludge is mixed with a certain proportion of auxiliary materials (e.g. straw, woodchips, etc.) to regulate the ratio of carbon and nitrogen and to improve the permeability, etc.;

After that, the mixture is sent into the fermentation equipment, under the suitable temperature, humidity and ventilation conditions, using the decomposition of microorganisms, the organic matter in the sludge is transformed into stable humus and other substances, to achieve harmless and stabilized treatment;

After the completion of the fermentation, the materials are sieved to remove impurities that are not completely decomposed, and finally, according to the needs of the qualified materials are pelletized, dried, packaged, and other processes, to make a sludge fertilizer products that can be directly used in agricultural production.

Specific application scenarios of sludge fertilizer production line

Fertilizers produced by sludge fertilizer production line are widely used in many fields. In agricultural planting, it can be used as base fertilizer for field crops such as wheat and corn planting to increase the yield and reduce the amount of chemical fertilizer, and it can enhance the yield and quality of economic crops such as vegetables and fruit trees planting;

In gardening, it can be used in lawn and flower maintenance of city parks and tree maintenance of green belts on the roads to improve the fertility of the soil and the resistance of the plants;

In ecological restoration, it can improve the soil of mine waste land to increase the vegetation cover, and it can promote the growth of plants in wetlands to enhance the ecological function.

In the field of ecological restoration, it can be used to improve the soil and increase the vegetation cover of the abandoned land of mines, and it can be used to promote the growth of plants and enhance the ecological function of wetlands, thus contributing to the ecological improvement.

The sludge to organic fertilizer production line is a sustainable development model that not only solves the problem of sludge disposal, but also provides agriculture with environmentally friendly fertilizer.

With society’s focus on environmental protection and resource cycling, such a production line will play an increasingly important role in the future, contributing to the construction of eco-friendly civilization. For more information,Pro consult us at Fuder Machinery!

Organic fertilizer equipment,organic fertilizer production line,organic fertilizer equipment factory

Organic fertilizer equipment,organic fertilizer production line,organic fertilizer equipment factory