You may be a large farm owner with a lot of animal waste. You could be an investor looking for a profitable business in the green economy. The answer for you might be commercial organic fertilizer production.

This business takes low-cost, or even free, organic waste and turns it into a high-demand, profitable product. At Fude Machinery, we see this as one of the smartest ventures in modern agriculture.

We are an equipment manufacturer, but we are also your partner in building this business from the ground up. This guide provides a clear business plan. We will show you the process, the necessary machinery, and how to make smart financial decisions to ensure your success.

Table of Contents

Is Commercial Organic Fertilizer Production a Profitable Business?

Yes, it is a very profitable business. The market is growing quickly. This is because more people want organic food, governments are supporting sustainable farming, and the raw materials are extremely cheap.

The commercial organic fertilizer production model is simple yet powerful. Take materials often seen as waste, like chicken manure or cow dung, which farms often pay to dispose of, and add value.

Demand for high-quality organic fertilizer is rising as farmers seek alternatives to chemical fertilizers that harm soil. This creates a business opportunity with low-cost inputs and high-demand, premium-priced outputs, yielding high profits.

Beyond animal manure, waste like mushroom substrate, crop straw, and food residues can also be used. As a manufacturer that has set up hundreds of such plants, we’ve seen well-run operations become profitable quickly.

What is the Initial Investment for a Fertilizer Plant?

The initial investment cost can range from around $50,000 for a small-scale line to over $500,000 for a large, highly automated plant. The biggest factor in this cost is the equipment for the complete production line.

Starting a commercial organic fertilizer production business requires a significant capital investment. The largest part of this investment will be in the machinery itself. The price of the equipment depends directly on the production capacity you want to achieve, which is measured in tons per year.

A smaller line with a capacity of 10,000 tons per year will be much less expensive than a large line that can produce 100,000 tons per year. Another major factor is the level of automation. A more automated line will require fewer workers, which can lower your long-term operational costs, but the initial machine investment will be higher.

Beyond the machinery, you must also budget for other essential costs. You will need a suitable piece of land and a factory building or shed to house the equipment. You will need to consider the logistics of bringing raw materials to your plant and shipping the finished product out.

You will also have costs for utilities like electricity and water, as well as the salaries for your workers. When you partner with us at Fude Machinery, we do more than just sell you machines. We provide a full consultation to help you understand all these costs.

We work with you to design a complete fertilizer production line that fits your specific budget and business goals. We provide a detailed quotation that breaks down the cost of every machine so you can make an informed financial decision.

What Are the Core Production Steps and Machines?

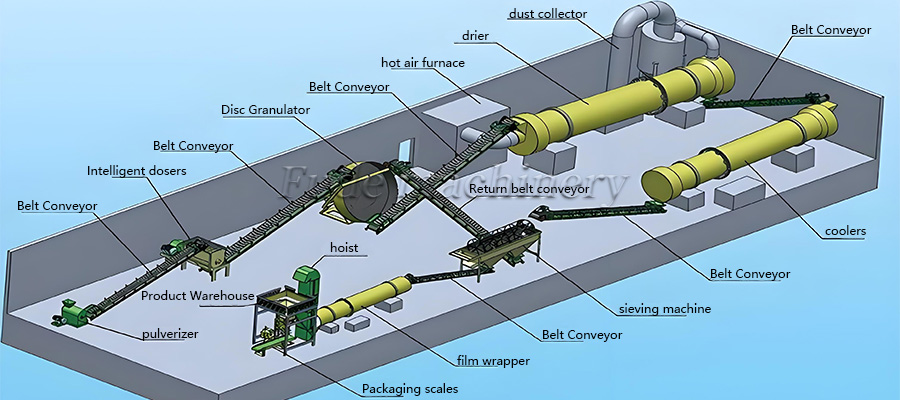

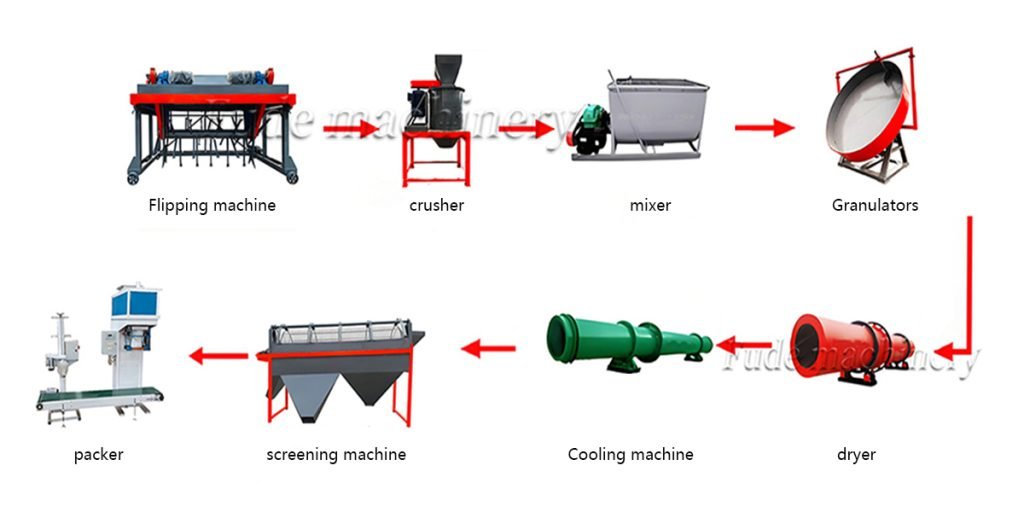

A complete commercial organic fertilizer production line has five main stages. These are fermentation (composting), crushing and mixing, granulation, finishing (drying, cooling, screening), and packaging. Each stage requires specific, robust machinery to work efficiently.

To be successful, you cannot take any shortcuts in the production process. Each step is crucial for creating a high-quality, stable, and valuable product. As your equipment partner, we provide all the necessary machines and ensure they work together seamlessly.

Step 1: Fermentation with a Compost Turner

This is the first and most critical step. Raw manure is full of harmful pathogens. The fermentation process, or composting, uses microorganisms to decompose the organic matter. This process generates heat that kills pathogens and creates a stable, nutrient-rich material. To speed this up, you need a compost turner. This machine flips and aerates the material, ensuring the microbes have the oxygen they need to work fast.

Step 2: Crushing and Mixing

After composting, the material will be lumpy. It must be crushed into a fine powder before it can be granulated. We use a specialized semi-wet material crusher that does not clog with moist material. After crushing, the powder goes into a large horizontal mixer. Here, you can add other nutrients to create a custom blend for your customers.

Step 3: Granulation – The Heart of Your Plant

This step turns your powder into pellets. For commercial production of organic fertilizer, the best machine is the New Type Organic Fertilizer Granulator. It uses a powerful high-speed stirring force to form dense, round pellets from wet and fibrous organic material. It has a high success rate (over 90%), which means less recycling and higher output for your plant. This machine is far more efficient and reliable for this specific task than a simple disc granulator.

Step 4: Drying, Cooling, and Screening

The new pellets are wet and hot. They must be dried to prevent mold and then cooled to prevent caking in the bag. A rotary drum dryer and cooler handle this efficiently. After cooling, a screening machine sorts the pellets. It separates the perfect-sized pellets and sends any oversized or undersized ones back into the system. This guarantees a uniform, high-quality product.

Step 5: Automatic Packaging

The final step is to weigh the finished pellets into bags. An automatic fertilizer packaging machine does this quickly and accurately. This machine ensures every bag has the correct weight and is sealed professionally, ready for the market.

How Do You Choose the Right Production Scale?

You should choose your production scale based on three key factors: the amount of raw material you have consistently available, the size of your target market, and your total investment budget. Starting with a realistic scale is crucial for success.

It can be tempting to want to build the biggest plant possible. However, the smartest business decision is to choose a scale that you can comfortably support and grow from. The first thing you must analyze is your raw material supply.

For example, if you own a chicken farm with 500,000 birds, you will have a consistent and large supply of manure. This amount of raw material can easily support a medium-scale production line. If you only have a smaller farm, a small-scale line is a more logical starting point. You must have a reliable source of material to keep your plant running.

Next, you need to research your target market. Are you planning to sell the fertilizer to local farms in your county? Or are you aiming to distribute it across an entire state or country? The size of your potential market will help determine the production capacity you need.

There is no point in producing 50,000 tons of fertilizer if you can only sell 10,000 tons locally. Finally, your budget is the ultimate deciding factor. It is better to build a high-quality, efficient small-scale line that you can afford than to build a low-quality large-scale line by cutting corners on machine quality.

At Fude Machinery, we often advise our clients to start with a modest, well-planned line. You can design your factory layout with space for a second production line to be added in the future as your business grows.

Frequently Asked Questions (FAQ)

Question 1: How much factory space is needed for a commercial organic fertilizer plant?

The space depends on the scale. A small-scale line (10,000 tons/year) might require around 2,000-3,000 square meters. A larger line (50,000 tons/year) could need 8,000-10,000 square meters. This includes space for raw material storage, the production line, and finished product warehousing.

Question 2: How long does it take to get a plant operational?

From the time you place an order with us, it typically takes 30-45 days for us to manufacture the complete set of machines. Shipping can take another 20-40 days depending on your location. Installation and commissioning on-site usually take about 15-30 days. In total, you can expect to be operational in about 3 to 5 months from your order date.

Question 3: Does Fude Machinery provide installation and training?

Yes, we do. Our full-service support includes sending our experienced engineers to your factory site. They will guide the installation of the equipment, commission the production line to ensure it runs smoothly, and provide hands-on training for your local workers on how to operate and maintain the machinery.

Conclusion: Your Partner in a Profitable Venture

Starting a commercial organic fertilizer production business is a clear and achievable path to profitability. The market demand is strong and growing. The business model of converting low-cost waste into a high-value product is fundamentally sound. The process is straightforward when broken down into its five core stages: composting, preparation, granulation, finishing, and packaging. The key to success is making smart decisions about your production scale and, most importantly, choosing a reliable equipment partner who understands the entire business.

About Fude Machinery

We are Fude Machinery, a specialized B2B manufacturer of organic fertilizer equipment located in Zhengzhou, China. Since our establishment in 2015, we have been committed to providing factory-direct sales and comprehensive, one-stop solutions. We have helped entrepreneurs and companies in over 120 countries build successful fertilizer businesses with our robust and efficient machinery.

Are you ready to turn your waste into wealth? Contact our expert team today.

Let’s discuss your project, and we will provide you with a free, customized business plan and equipment quotation to get you started.

Organic fertilizer equipment,organic fertilizer production line,organic fertilizer equipment factory

Organic fertilizer equipment,organic fertilizer production line,organic fertilizer equipment factory