Optimizing the pig manure drying process is crucial for industries dealing with high moisture organic wastes. Efficient water reduction not only improves the quality of the final product but also enhances environmental sustainability.

Understanding the best practices and equipment involved can lead to significant benefits across various sectors that rely on organic fertilizers and composting materials.

What Are High Moisture Organic Wastes and Their Challenges?

High moisture organic wastes, such as swine dung, food waste, and agricultural residues, often contain moisture content exceeding 90%. These materials present significant challenges in waste management due to their high water content, which increases transportation costs and hinders further processing.

Excessive moisture promotes the growth of pathogens and leads to unpleasant odors, posing environmental and health risks. Effectively reducing the moisture content is essential to transform these wastes into valuable resources while mitigating negative impacts.

How Can Different Industries Benefit from Pig Manure Water Reduction?

Various industries can reap substantial benefits from efficient pig manure dehydration processes. In the composting industry, reducing the moisture content accelerates decomposition, resulting in high-quality compost with enhanced nutrient availability.

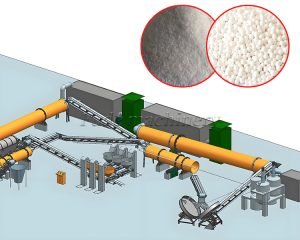

Fertilizer manufacturers can produce granules or pellets with consistent size and nutrient composition, improving product marketability and application efficiency. Biomass energy producers can utilize dehydrated swine manure as a renewable energy source, contributing to sustainable energy solutions and reducing reliance on fossil fuels.

Livestock farms also benefit by managing waste more effectively, reducing environmental pollution, and potentially generating additional revenue streams.

What Equipment Is Essential for Effective Pig Manure Dehydration?

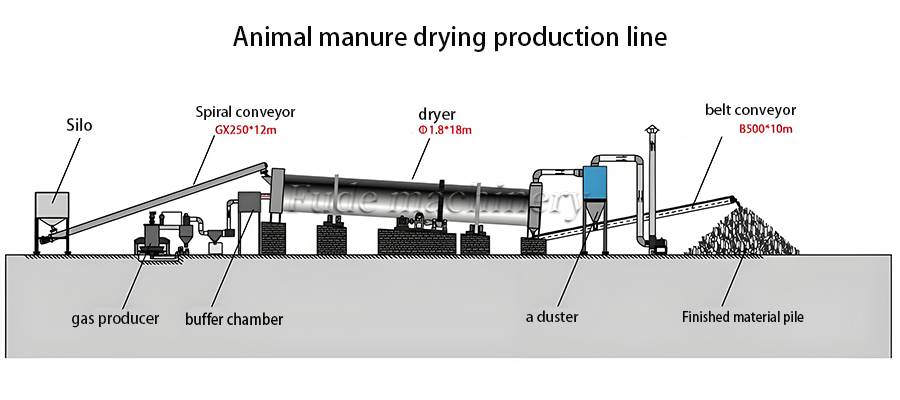

Implementing the right machinery is crucial for maximizing efficiency in the pig manure drying process. A comprehensive system typically involves four stages: dewatering, composting, granulating, and drying.

The dewatering machine mechanically removes excess water, significantly reducing the moisture content and volume of the material. Composting equipment facilitates aerobic decomposition, transforming organic waste into stable compost while further reducing moisture.

Wet granulators convert the compost into uniform particles or pellets, enhancing ease of handling, storage, and application. Finally, the dryer reduces the moisture content to below 10%, ensuring the stability and longevity of the final product. Each piece of equipment is designed to work synergistically, streamlining the production process and optimizing efficiency.

Pre-treatment before drying: Improvement of raw material homogeneity and controllability of moisture content

solid-liquid separation

- Screw extrusion separator: 70%-80% of the water in pig manure is removed by physical extrusion, which reduces the initial water content to 65%-70% and reduces the subsequent drying energy consumption.

- Centrifugal dewatering machine: suitable for large-scale processing, higher dehydration efficiency, but higher equipment cost.

Grinding and mixing of raw materials

- Crusher: refine the pig manure particles to 3-5mm, increase the surface area and improve the drying efficiency.

- Mixer: add straw, sawdust and other auxiliary materials, adjust the carbon and nitrogen ratio to 25:1-30:1, and at the same time reduce the moisture content to 55%-60% to optimize the fermentation and drying conditions.

Fermentation Pretreatment

- Aerobic fermentation: decompose organic matter through microbial action, generate heat, further reduce water content to 40%-50%, and at the same time kill pathogenic bacteria and reduce odor.

What are the benefits of optimizing hog manure drying?

Optimization of pig manure drying can bring significant comprehensive benefits: through technological upgrading, the water content will be reduced from 80% to less than 15%, so that the volume of manure will be reduced by more than 70%, which will greatly reduce the cost of transportation and storage.

After drying, pig manure can be processed into high value-added organic fertilizers (the market selling price is increased by 3-4 times), and the nutrient utilization rate will be increased by 60% compared with the original manure, which will guarantee the ecological safety of the soil.

In addition, the supporting waste heat recovery technology can reduce the energy consumption by 35%-45%. In addition, supporting waste heat recovery technology can reduce energy consumption by 35%-45%, and if combined with biogas power generation to achieve cogeneration, the cost per ton of treatment can be reduced by 50%-60%, forming a green industry chain of “pollution reduction – value-added resources – energy cycle”, which not only solves the problem of waste treatment in farming, but also promotes the development of agricultural industry.

This will form a green industrial chain of “pollution reduction-value-added resources-energy circulation”, which not only solves the problem of farm waste treatment, but also promotes the realization of the goal of agricultural carbon neutrality.

How to Choose the Right Pig Manure Drying Technology?

Selecting the appropriate technology for pig manure drying involves considering factors such as processing capacity, energy consumption, and desired end-product characteristics. Assessing the scale of operations and specific industry needs is essential.

For instance, small-scale farms may prioritize cost-effective solutions with lower energy requirements, while large-scale fertilizer producers may focus on high-capacity systems with advanced automation features. Evaluating the technical specifications, durability, and after-sales support of the equipment can also influence the decision-making process.

Through the above optimization measures, the efficiency of pig manure drying process can be improved by more than 50% and energy consumption can be reduced by more than 30%, and at the same time, the win-win situation of environmental protection and economic benefits can be realized.

Organic fertilizer equipment,organic fertilizer production line,organic fertilizer equipment factory

Organic fertilizer equipment,organic fertilizer production line,organic fertilizer equipment factory