The use of animal manure to process organic fertilizer is a new industry. Such industries are supported by national policies, sought after by market funds, and their products are welcomed by growers.

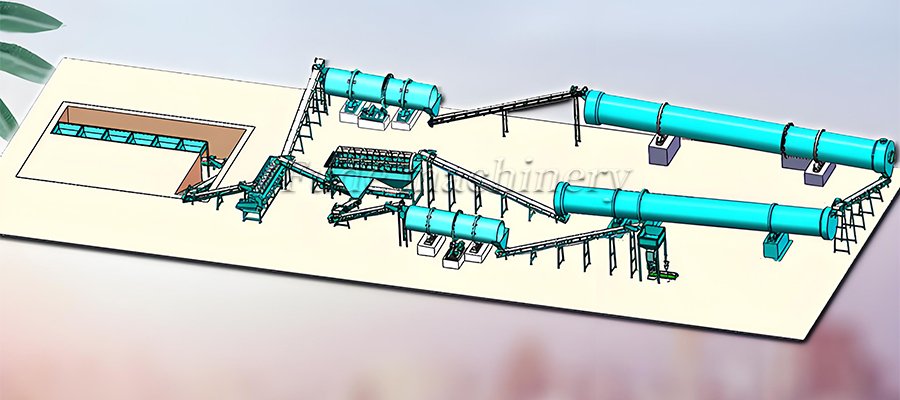

Such hot products are divided into powder organic fertilizer production lines and granular organic fertilizer production lines.

Whether it is powder or granule, it is divided into three categories according to the output: large, medium and small organic fertilizer production lines. Today, I will talk about the powder organic fertilizer making line in detail.

The powder organic fertilizer preparation line has the advantages of simple equipment and process, convenient operation of the production line, low investment cost, convenient maintenance and so on.

As the pre-process of granular organic fertilizer production line, the process of powder organic fertilizer production line is simply crushing, fermentation and packaging.

The organic fertilizer fermentation equipment used in this set of organic fertilizer production lines is aerobic fermentation bacteria, which has the characteristics of fast heating, good deodorization effect, and thorough decomposing.

It is suitable for static fermentation and dynamic fermentation mode, and can effectively treat livestock and poultry manure and Solid organic matter, such as crop straw, straw, pine husk, peanut husk, rice bran, sawn wood, leaves, mushroom leftovers, medicinal residue, sugar mash, distiller’s grains, bagasse, monosodium glutamate residue, furfural residue, protein and The crude fiber is rapidly heated, deodorized, sterilized and decomposed.

Constant temperature control for about 15 days can completely kill viruses, germs, insect eggs, and weed seeds, and achieve harmless treatment, so as to effectively curb the occurrence of soil diseases and insect pests and reduce the amount of pesticides. Click here to learn more

The main product form of the powder organic fertilizer production line is presented in powder form, and the active ingredients account for more than 90%. It is a high-quality organic fertilizer.

Things You Must Know In Cow Dung Organic Fertilizer Making

What you need to pay attention to in the production process of cow dung organic fertilizer:

First of all, the location of the cow dung organic fertilizer plant is very critical. It is close to the raw materials. The raw materials of organic fertilizers are generally obtained locally. If the supply of raw materials is guaranteed through long-term transportation, the cost will increase a lot.

After the cow dung enters the fermentation tank and starts to ferment, it is necessary to observe the moisture and temperature of the cow dung at any time during the fermentation, control the changes of the raw materials in time, and make timely treatment.

Use the organic fertilizer fermentation turning machine to turn the heap to ensure the uniform and full fermentation of the cow dung. Fermentation bacteria can be added during fermentation to speed up the aerobic fermentation

But it is not recommended to add other biological bacteria during this period, because the temperature of the material is very high during fermentation, and many beneficial bacteria cannot withstand high temperatures. Click here to know more

After the cow dung is fermented, it is sent by the conveyor to the forklift silo for use. This silo is generally equipped with a speed regulation function, which can well control the feeding speed of the rear lingering equipment. After coming out of the silo, it enters the mixer. At this time, some auxiliary materials can be added to the raw materials

. Generally, we recommend designing two mixers, one for mixing and one for discharging. After the material is stirred evenly, it need to be crushed. The organic fertilizer crusher is not the same as the general crusher.

Since we need the material to maintain a certain amount of moisture, the crusher should use a semi-wet material crusher. 20%-50%, fully capable of crushing our organic fertilizer raw materials.

Granulation affects the forming effect of the entire cow dung fertilizer production line, so the choice of granulator is very important. According to the different raw materials, the models we want to use are also different.

For example, we use cow dung as the raw material of organic fertilizer, and add some other organic substances (straw, sawdust, etc.) appropriately, we reommend you use organic fertilizert stirring teeth granulator, this model uses the match between the stirring teeth and the cylinder wall to force the fertilizer material into granules, and it is better for some livestock and poultry manures with relatively thick fibers.

Another thing to pay attention to is drying. We all know that organic fertilizer needs to add certain biological bacteria, but too high temperature will kill and reduce the survival of biological bacteria, so temperature control is very important.

If the output of cow dung organic fertilizer is large, we generally recommend adding drying equipment and lowering the temperature to ensure the survival of biological bacteria. It is also possible to consider adding a coating cylinder after drying to directly wrap biological bacteria on the surface of the material.

If you want to learn more about cow dung fertilizer making, Please consult us at Please consult us at Fude Machinery Equipment Manufacturer.

Organic fertilizer equipment,organic fertilizer production line,organic fertilizer equipment factory

Organic fertilizer equipment,organic fertilizer production line,organic fertilizer equipment factory