With the country’s further emphasis on environmental protection, livestock and poultry manure in the breeding industry is also one of the main sources of environmental pollution.

But at the same time, if the livestock and poultry manure is processed, it is also a valuable organic fertilizer resource.Through processing animal manure into quality fertilizer can not only turn waste into treasure, but also realize the reuse of resources.

At the same time, it can also reduce the pollution of the environment and prevent the spread of diseases.

Then what is the process of manure fertilizer making?

First of all, we need to ferment the collected livestock and poultry manure. There are many ways to ferment. You can choose a fermenter to ferment, build a fermenter to store in a fermenter, or the most primitive stacking for fermentation.

It is necessary to add corresponding auxiliary materials (straw, bean dregs, humic acid, etc.) to ferment the fermentation tank or fermenter to increase the organic matter in the raw materials and accelerate the fermentation stage.

The fermentation agent has the main functions of deodorizing, sterilizing, decomposing harmful substances in livestock and poultry manure, killing weeds, and accelerating the fermentation cycle.

The original composting fermentation has a long fermentation period, which pollutes the environment more, and the harmful substances in the manure of livestock and poultry cannot be effectively removed.

In the tank fermentation, it is necessary to turn over the manure of livestock and poultry, so that the microbial agent can better reproduce and decompose the harmful substances in the raw materials.

Therefore, in the fermentation stage, it is necessary to use compost making machine (hydraulic turning machine, roulette turning machine, chain plate turning machine, etc.).

After the materials are fermented, turned and decomposed, they need to be transported to the secondary storage area with a forklift.

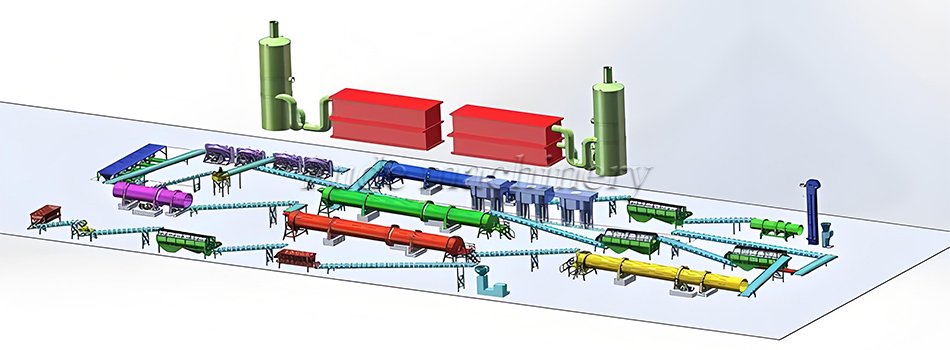

Use a forklift to transport the material to the organic fertilizer forklift feeding bin, and through the uniform feeding and unloading of the forklift feeding bin, use the belt conveyor to transport the material to the organic fertilizer semi-wet material grinder for crushing.

The material crushed by the pulverizer is transported to the organic fertilizer powder screening machine through the belt conveyor. The screened material can be directly packaged into powder organic fertilizer, and can also be used as the raw material of granular organic fertilizer. Click here for organic fertilizer business plan

If it is necessary to add nitrogen, phosphorus and potassium (NPK) elements to the sieved powdered organic fertilizer to make organic compound fertilizer, the powdered raw material and nitrogen, phosphorus and potassium (NPK) need to be transported to the organic fertilizer horizontal mixer in a certain proportion for stirring Mixing, conveying to the organic fertilizer granulator machine(new organic fertilizer granulator, disc organic fertilizer granulator, drum organic fertilizer granulator, stirring tooth organic fertilizer granulator, etc.)

through the belt conveyor for granulation , the particles are transported to the organic fertilizer dryer by the belt conveyor for drying, and then transported to the organic fertilizer cooler by the belt conveyor for cooling after drying, and the cooled particles are transported to the organic fertilizer particle screening machine by the belt conveyor for further processing.

The finished product is screened, and the unqualified products are pulled back to the pulverizer through the return belt conveyor for pulverization or directly equipped with the pulverizer for pulverization, and then continue to the granulation stage after pulverization.

The finished product that passes through the organic fertilizer screening machine is transported to the organic fertilizer finished product silo by a belt conveyor, temporarily stored in the finished product silo, and then packaged by an organic fertilizer automatic packaging machine.

Packed and stacked in the finished product area. If you want know more organic making systems,You can consult us Fude Machinery.

In the end, the harmful livestock and poultry manure becomes an organic fertilizer that is beneficial to the land and the environment. The centralized and harmless treatment of livestock and poultry manure has also produced certain economic benefits.

It has avoided environmental pollution for the environment and provided high-quality organic fertilizers for the land. It really serves multiple purposes.

Organic fertilizer equipment,organic fertilizer production line,organic fertilizer equipment factory

Organic fertilizer equipment,organic fertilizer production line,organic fertilizer equipment factory