Due to increased technology, poultry feed pellet mill is among the new machines in the market. They are making it easier to make pellets for a various variety of animals like fish, sheep, cattle, poultry, rabbit, chicken, duck, cheese, geese among others.

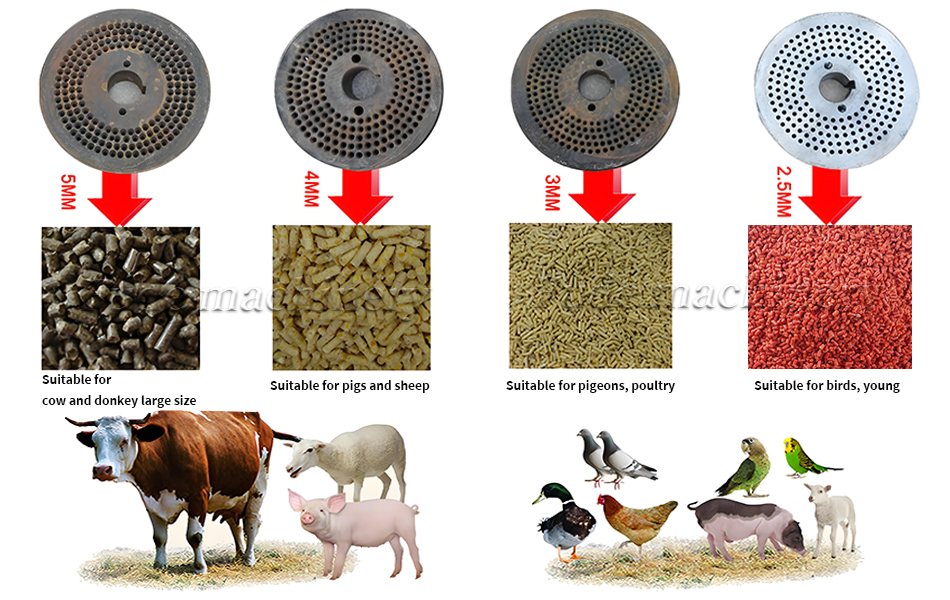

The machine is able to make pellets of a diameter ranging from 2mm to 8mm. It has a capacity of producing 600kg/hour to 1000kg/hour. This means you can control the speed of production depending on the demand in the market. The machine is a great boost to small-scale farmers in the market since they can invest in the small amount of money they have with the machine.

Advantages of the Poultry Feed Pellet Mill Unit

- It has a low production cost: The machine does not require too many people to operate. In fact, it requires just one or two people to operate it. This greatly cuts the cost of labor that largely affects the production cost. Low production cost leads to increase in the profit margin.

- Reduced installation cost: The machine is simple and small hence it is easier to purchase and install it. You only need a few minutes to assemble the different parts. This reduces the amount of cash required to call a qualified personnel to assemble it. You only need one qualified personnel and another to help him.

- It¡¯s a low investment machine: Due to its small size, the pellet machine requires a small area. This reduces the cost of hiring a big area of installing it and also the time required to install it.

- Has a wide application: The machine is capable of producing different sizes of pellets for different poultry and livestock animals. This means you can feed all your animals using one machine at the same time. It has made it easier for the farmers to rear different types of animals in their farms.

Fude Machinery is a reliable feed pellet machine supplier in China, with decades of experiences in livestock and poultry feed manufacturing process.This small feed plant is one of our hot sell equipment for small poultry feed making factories around the world espacially in India.

If you want to buy chicken feed pellet mill for starting your own mini poultry feed factory, it should be your best choice! Whenever you are interested in our equipments for making feed pellets, don’t hesitate to get in touch!

Poultry Feed Pellet Making Process

Poultry feed pelletizing process is a key link in feed processing, which directly affects the quality, nutritional value and feeding effect of feed.

The core process can be divided into four major steps: raw material crushing, mixing, pelletizing, cooling and post-processing, the following is a detailed description of the specific process:

This is the first step to ensuring all the large grains are crushed into powder forms. The pellet mill has a grinding machine that is specifically for the crushing purposes. Maize meals, broomcorn, wheat, beans, oilseed meal, soya bean meal may be in large grains and hence must pass the process. They are taken to the crushing machine where they are crushed into fine powder. Without this process, it might be next to impossible to make pellets.

This is where all the ingredients are mixed. The mixing machine is known as 9HLP vertical mixing machine. It has a large barrel where all the ingredients are put in different proportions. With the help of the machines, the powder is mixed in different proportions to form one mixture which is known as feed mesh.

The pelletizing system consists of a pelletizer for poultry feed which is used to extrude the feed web and make pellets. It is capable of making pellets of uniform size, including the same diameter and length. This ensures that the poultry feed pelletizer produces the required sizes for different animals to ensure that what is needed is provided and waste is avoided when feeding. Our feed pelletizer is widely used in small chicken feed production line and small cattle feed pelletizer.

After crushing, mixing and pelletizing the final process is cooling. The machine used here is the KLN series counter flow type cooler. The machine is small in size and convenient when transporting and installing. At the pelleting system, the pellets tend to produce heat which ranges from 70 to 85 degrees.

This heat must be reduced to room temperature to meet the storage requirement. Without cooling process, the hot pellets would produce mildew resulting to damage of the pellets. With a cooling fan in place, the pellets pass through the cooling area and their temperature is reduced to harmless levels. The pellets are then packed and stored in a cool dry place.

As a leading pellet equipment supplier in China, Fude Machinery offers a wide and complete line of feed pellet mills with capacities ranging from small to large, from 80 kilograms per hour to 15 tons per hour, as well as complete production lines.

The company will continue to provide higher quality feed pellet mill solutions to customers around the world under the business philosophy of “Quality First, Customer First”.

Organic fertilizer equipment,organic fertilizer production line,organic fertilizer equipment factory

Organic fertilizer equipment,organic fertilizer production line,organic fertilizer equipment factory