I am part of Fude Machinery. We work with large farm owners and agricultural entrepreneurs around the world. I know the challenges you face. You have a constant supply of animal waste, like chicken manure or cow dung. This waste is a disposal problem. It can cause environmental issues and is costly to manage. But what if you could look at that pile of waste and see a pile of money? You can. The process of turning animal waste into high-quality organic fertilizer is a proven and profitable business model. It turns a liability into a valuable asset. I will guide you through the essential steps. I will show you how a modern organic fertilizer machine production line makes this transformation efficient and straightforward.

Step 1: Composting – The Foundation of Quality Fertilizer

You must compost the raw animal manure first. This biological process is essential to kill harmful pathogens, eliminate foul odors, and create a stable, nutrient-rich base material for your fertilizer.

I cannot overstate this. You cannot simply take fresh manure and put it into a granulator. Raw manure contains harmful bacteria like E. coli and Salmonella. It also has a very strong, unpleasant odor. The composting process solves these problems. It is a controlled decomposition process where beneficial microorganisms heat the manure pile to high temperatures (55-65°C). This heat sterilizes the material, killing weed seeds and pathogens. It also breaks down the organic matter into a stable, nutrient-rich humus that is perfect for plant growth.

To do this efficiently on a commercial scale, you need a specialized machine. At Fude Machinery, we recommend a Compost Turner. This machine drives over the long piles of manure, called windrows. It lifts, turns, and aerates the material. This action provides the oxygen the beneficial microbes need to work quickly and effectively. Without a turner, the process could take many months. With a turner, you can produce fully composted material in just 15-20 days. This is the first and most critical step in your professional organic fertilizer machine line.

Step 2: Crushing – Creating a Uniform Powder

After composting, the material will be lumpy and may contain clumps. You must crush it into a fine, uniform powder. This step ensures that the granulation process will be smooth and the final pellets will be consistent.

The composted material is great, but it is not ready for granulation yet. It will have an uneven texture with both fine particles and larger, caked lumps. If you try to feed this directly into a granulator, you will get inconsistent results. The machine will struggle to form uniform pellets. To solve this, you need a Fertilizer Crusher.

We typically use a Semi-Wet Material Crusher for this stage. It is designed to handle composted material that still has a bit of moisture (around 25-35%). It uses high-speed rotating blades to smash the lumps against a durable inner casing, instantly turning them into a fine, consistent powder. This powder is the ideal input for the next stage. Think of it like a baker sifting flour before making dough. This step ensures there are no lumps and the final product will have a smooth, professional quality. A uniform powder base leads to a uniform final pellet. It is a non-negotiable step for quality control.

Step 3: Granulation – The Heart of the Process

Granulation is the magical step where you turn the fine compost powder into solid, easy-to-handle pellets. For wet and sticky animal manure compost, the New Type Organic Fertilizer Granulator is the best machine for the job.

This is the core of your operation. This is where your product takes its final shape. As I mentioned, composted manure is still moist and sticky. This is a huge problem for many granulators, but it is a perfect condition for our New Type Organic Fertilizer Granulator. This is the organic fertilizer machine that directly competes with the one you saw from other suppliers. Here is why ours is superior for this specific task.

This machine uses a unique process. Inside a strong steel cylinder, a central shaft with many small stirring “teeth” spins at an incredibly high speed. This creates a powerful force. The fine, moist powder is fed in, and the force of the spinning teeth makes the particles collide and stick together. The machine uses the material’s own moisture as a natural binder. Crucially, the teeth are constantly scraping the inside of the machine. This makes it self-cleaning and prevents the sticky compost from building up and causing clogs. It is designed to run continuously with minimal downtime, turning your tricky raw material into dense, uniform pellets with a success rate of over 90%.

Why Not Other Granulators for Manure?

- Disc Granulator: This is a great machine for creating perfectly round pellets, but it is more sensitive to very high moisture and fibrous materials found in manure. It is better for a premium finish, not for high-volume, tough raw material.

- Double Roller Granulator: This machine is for dry powders only. It uses pressure, not moisture. It would turn wet compost into a compressed sludge. It is the wrong technology for this application.

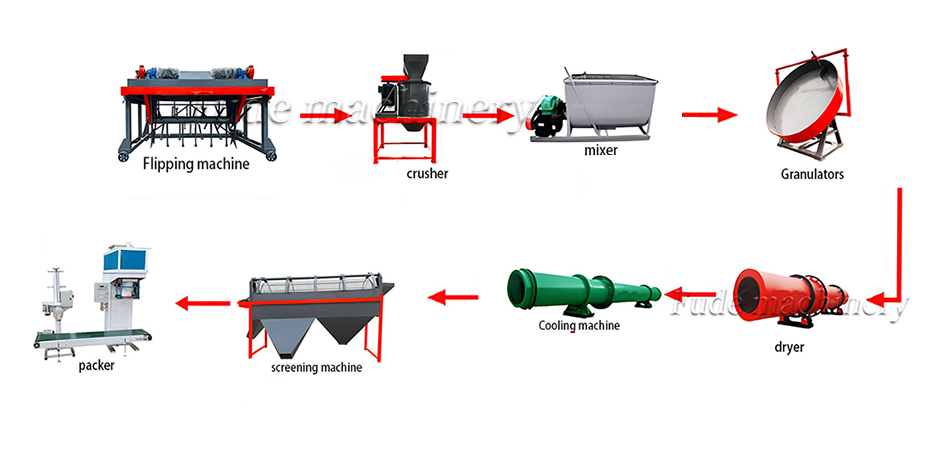

Step 4 & 5: Finishing, Screening, and Packaging

After granulation, you must dry and cool the pellets to ensure they are stable for storage. Then, you screen them for uniform size and package them for sale. These finishing steps guarantee a professional, market-ready product.

You are almost there. The pellets coming out of the granulator are warm and still have excess moisture. If you bag them immediately, they can grow mold or break down.

- Drying and Cooling: The pellets are fed into a large Rotary Dryer. This machine tumbles the pellets in a stream of hot air to reduce the moisture content to a stable level (below 15%). Immediately after, they go into a Rotary Cooler, which uses cool air to bring them back to room temperature. This hardens the pellets and prevents them from sticking together in the bag.

- Screening: Next, the cooled pellets are sent to a Rotary Screening Machine. This machine has a mesh of a specific size. Pellets that are the correct size pass through to the next stage. Pellets that are too big or too small are separated and sent back to the crusher and granulator to be re-processed. This ensures every bag you sell contains a perfectly uniform product.

- Packaging: The final step is the Automatic Fertilizer Packaging Machine. This machine weighs the exact amount of fertilizer, dispenses it into a bag, and heat-seals the bag shut. This is a fast, accurate, and professional way to prepare your product for the market.

This complete, interconnected system is what we call an organic fertilizer production line. Every machine works together seamlessly.

Frequently Asked Questions (FAQ)

Question 1: How much space do I need for a complete production line?

A small to medium line (1-3 tons per hour) typically requires a workshop area of about 500 to 800 square meters. This provides enough space for the equipment, raw material storage, and final product storage.

Question 2: What is the return on investment (ROI) for a plant like this?

The ROI is very attractive because your primary raw material (animal waste) is often free or very low-cost. The main costs are equipment, labor, and energy. Many of our clients see a full return on their investment in just 1-2 years, depending on their local market price for organic fertilizer.

Question 3: Can I add other nutrients to the fertilizer?

Yes. You can add other elements like Nitrogen, Phosphorus, and Potassium (NPK), or trace minerals. This is typically done in a mixing machine right before the granulation step. This allows you to create customized, high-value blended organic fertilizers.

Summary and Your Next Step

Turning animal waste into profit is not a dream. It is a practical and scalable business that we have helped hundreds of clients build. The process is clear. You must start with proper composting. Then you crush the material into a fine powder. You use the right organic fertilizer machine—the New Type Granulator—to handle the wet, sticky compost. Finally, you dry, screen, and package a professional product. By investing in a complete production line, you control the entire process, ensure high quality, and build a sustainable business.

About Fude Machinery

I speak for Fude Machinery, a specialist B2B manufacturer of organic fertilizer equipment located in Zhengzhou, China. Since 2015, we have provided factory-direct sales and complete, customized solutions to businesses in over 120 countries. We don’t just sell machines; we provide the engineering, installation, and support you need to succeed.

Contact our engineering team today. We will provide you with a free plant design and a detailed quotation based on your specific raw materials and production goals.

Organic fertilizer equipment,organic fertilizer production line,organic fertilizer equipment factory

Organic fertilizer equipment,organic fertilizer production line,organic fertilizer equipment factory