In the ever-evolving world of agriculture, innovation and technological advancements are the driving forces for increased productivity and efficiency. One such innovation that has transformed the fertilizer production landscape is the Disc Granulator. This blog post is dedicated to providing an in-depth overview of this revolutionary machine. If you want to learn more about biochar disc granulator, you can click here to view more.

The Biochar Disc Granulator, a key player in the fertilizer production industry, is a piece of equipment that meticulously shapes raw materials into specific sizes and shapes. Granulation, the process it employs, plays a pivotal role in enhancing the physical characteristics of the fertilizer, thus ensuring effectiveness when applied to soil.

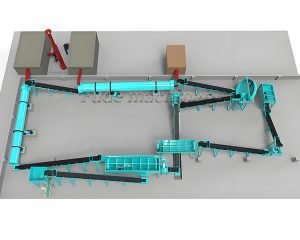

The Disc Granulator machine boasts a large rotating disc at its core, strategically angled and edged to granulate raw materials efficiently. As the disc turns, the raw material, usually a nutrient concoction, is introduced into the machine. It is this rotating motion that transforms the material into compact, uniform granules.

One significant advantage of the carbon-based Disc Granulator is its ability to produce consistent granules. This uniformity is paramount in ensuring the even distribution of nutrients when applied to soil. Coupled with its high efficiency, the machine can produce large quantities of granules within a short timeframe, thereby enhancing productivity.

Flexibility is another notable feature of the Disc Granulator. The ability to control the size of the granules by merely adjusting the angle of the disc or the moisture content of the material provides a level of customization. This adjustability ensures the production of various granule types to cater to diverse agricultural needs.

The robust design of the charcoal-based Disc Granulator is a testament to its longevity and reliability. Built from high-quality, durable materials, it can withstand high pressures and wear, thereby prolonging its lifespan and reducing maintenance downtime.

The Disc Granulator also scores high on environmental impact. By converting raw materials into compact granules, the machine significantly reduces dust pollution, making transportation and application easier. This feature is a win-win, benefiting both manufacturers and contributing to environmental conservation efforts.

Revolutionizing Fertilization: The Impact of Carbon-based Fertilizer Disc Granulator

As an organic farmer or a fertilizer manufacturer, you might be aware of the importance of soil fertility. In recent years, the significance of carbon-based fertilizers in nurturing fertile soil has skyrocketed. This brings us to an amazing piece of machinery that every organic farmer or fertilizer manufacturer should consider investing in – The Carbon-based Fertilizer Disc Granulator.

The Biochar Fertilizer Disc Granulator is a game-changer in the realm of organic farming. It is designed to transform powdered carbon-based fertilizers into granules. The granulation process increases the spreadability and absorption rate of the fertilizers, thus enhancing their effectiveness in enriching the soil.

One of the striking features of the char-based disc granulator is its high efficiency. It can process a large amount of powdered fertilizer in less time, significantly reducing production time and cost. Moreover, this machine ensures uniformity in the granule size, leading to consistent quality of the final product.

Another major advantage of the Carbon-based Fertilizer Disc Granulator machine is its versatility. You can adjust it to produce granules of different sizes according to your requirements. This means you can fine-tune the granule size to suit your soil type and crop pattern.

Durability is another key aspect of this granulator. Built to withstand heavy-duty work, it maintains its efficiency over the long term. This not only ensures a lengthy service life of the machine, but it also minimizes the need for frequent maintenance and replacement.

In the context of environmental sustainability, the disc granulator stands out. By converting carbon-based fertilizers into granules, it cuts down on dust pollution that otherwise occurs during the application of powdered fertilizers. The granulator also promotes the recycling of agricultural waste into useful organic fertilizers, thereby reducing waste and supporting sustainability.

In conclusion, the Disc Granulator is indeed an asset in the fertilizer industry. Its efficiency, adaptability, durability, and environmentally-friendly operation make it a must-have for all fertilizer manufacturers. The Disc Granulator is a classic example of how technology can enhance productivity while promoting sustainable practices. It is a testament to human ingenuity and our constant strive for improvement in the agricultural sector. In the end, if you want to learn more information, Please contact us Fude Machinery!

Organic fertilizer equipment,organic fertilizer production line,organic fertilizer equipment factory

Organic fertilizer equipment,organic fertilizer production line,organic fertilizer equipment factory