I often get questions about the different types of fertilizers. They want to know the real difference. Understanding this difference is very important. It helps you choose the right fertilizer for your farm or business. It also helps you understand how fertilizers are made. I will explain the core differences here. I will also tell you what this means for your operations.

Table of Contents

What is Granular Fertilizer and How is It Made?

Granular fertilizers are fertilizers that combine nutrients into a single homogeneous particle. Each particle contains a balanced combination of nutrients, which are chemically bonded or uniformly distributed to ensure that each particle has the same proportion of nutrients, and homogeneity is a key characteristic, and a wide range of processes are available to manufacture these fertilizers.

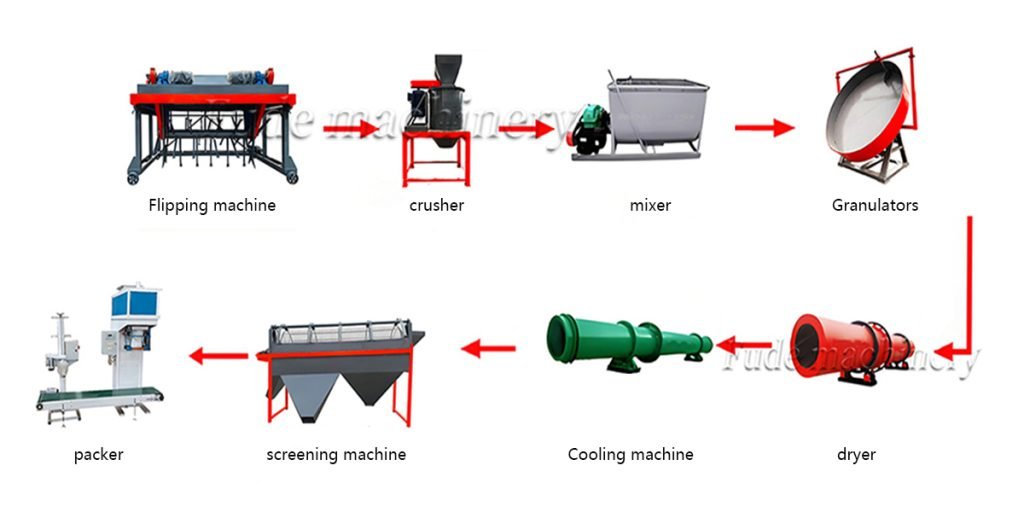

The process of manufacturing granular fertilizers is complex. Raw materials are prepared first, such as organic waste or compounds. Organic granular fertilizers start with fermentation, after which the material is crushed into a fine powder and then mixed with different nutrient sources (nitrogen, phosphorus, potassium and trace elements), which are thoroughly blended into a homogeneous mixture.

Next is granulation. Fude Machinery specializes in this stage and offers a wide range of granulators:

disk granulators use arotating disk to spray water to make the material into granules;

roller granulators use high pressure to compress the drymaterial into flakes and then pulverize it;

rotating drum granylators use a rotating cylinder to make the material intogranules;

stiring tooth granulators combine mixing and granulation, and the teeth produce friction to make the granulesagglomerated. After granulation, the granules are dried, cooled, screened to a uniform size and finally packed.

What is Blended Fertilizer and How is It Made?

Blended fertilizers (BB fertilizers) are bulk mixtures of two or more separate nutrient source fertilizers that have been made into granules and are physically mixed with the goal of creating the desired overall nutrient ratio.

It is simpler to manufacture than granular fertilizers and does not require a granulation step. Fertilizer components that have been granulated are first procured, the desired NPK ratio of the final mix is determined, and the exact weight of each component is calculated.

The pre-measured granular components are then mixed in a large mixer, which is rotated or paddled to homogenize the mixture. This process is short and there is no chemical reaction or physical transformation of the particles, which remain separate. After mixing, the mixture is transferred directly to storage or packaging without drying or cooling.

We provide conveying systems and packaging machines, and although we specialize in granulation, our downstream equipment can assist in the handling of the finished compound fertilizer.

What is the Essential Difference in Production?

The essential difference between granular fertilizer and blended fertilizer lies in how the nutrients are combined and distributed within the final product. This distinction profoundly impacts their uniformity and performance. I see this difference clearly in the machinery involved for each type.

The key to granular fertilizers is to process all nutrients together into individual pellets, each containing a precisely designed NPK ratio . During production, organic or inorganic raw materials are finely ground and mixed thoroughly, then fed into a granulator to be shaped into homogeneous pellets, where the nutrients are chemically bonded or mechanically bound to the pellets (special organic fertilizer granulation equipment is required). After granulation, the pellets are usually dried and cooled to enhance their strength and stability, resulting in a granular product with uniform chemical and physical properties.

Compound fertilizer production differs from granular fertilizers in that pre-made finished granules are accurately weighed and mixed in a large mixer to achieve the desired NPK ratio.

After mixing, the particles retain their identity and do not combine to form new particles. The individual particles removed from the fertilizer mix may be urea or diammonium phosphate, etc., and the proportioning is achieved by mixing the whole. Therefore, the final product does not require complex granulation, drying or cooling, but mainly mixing and packaging equipment.

To put it simply:

- Granular fertilizer: Each single pellet is a complete, balanced nutrient package.

- Blended fertilizer: The overall mixture is a complete nutrient package, but individual pellets within the mix are often single nutrient sources.

What Are the Key Implications for Application?

The production differences between granular and blended fertilizers have major implications. These differences affect how you store, handle, and apply the fertilizer. They also impact how effective the fertilizer is in the field. Understanding these points helps you make a better choice for your needs.

One big implication is nutrient uniformity during application. With granular fertilizer, every single granule contains the same nutrient ratio. When you spread it, each part of the soil gets a balanced amount of nitrogen, phosphorus, and potassium.

This promotes even crop growth across the field. You avoid patches where plants get too much of one nutrient and too little of another. This consistency is very beneficial for crop health and yield. It helps you maximize your return on investment.

On the other hand, blended fertilizers have a higher risk of segregation. The individual components in a blend might have different particle sizes or densities. Imagine mixing sand and pebbles. The pebbles tend to settle, and the sand stays on top. The same thing can happen with fertilizer blends. During transport, handling, or even in the spreader hopper, the different granules can separate.

This means one part of your field might receive more nitrogen. Another part might receive more phosphorus. This can lead to uneven crop growth. It can also lead to nutrient deficiencies or excesses in different areas. This unevenness can reduce overall crop yield. It can also waste fertilizer resources.

Finally, consider flexibility versus manufacturing cost. Blended fertilizers offer great flexibility. You can create custom NPK ratios very quickly and cheaply. This is great for precise nutrient management based on soil tests. Granular fertilizers, especially compound ones, are more expensive to produce.

They require more complex machinery and processes. However, their benefits in terms of uniformity and reduced segregation often outweigh the higher cost for many large-scale operations or specific applications. My company helps you with the higher-cost but higher-quality granular fertilizer production. We provide the equipment for the complete organic fertilizer production line .

How Fude Machinery Supports Both Types of Fertilizer Production?

My company, Fude Machinery, plays a crucial role in the fertilizer industry. We focus on providing high-quality equipment. This equipment primarily helps you produce granular organic fertilizer. Our expertise lies in the entire process of transforming raw organic materials into uniform, effective granules. However, our machinery also supports aspects of blended fertilizer production.

For granular organic fertilizer production, we offer a comprehensive range of machines. We start with the composting process. Our various types of compost turners ensure proper fermentation of organic waste. This prepares materials for granulation. After composting, our organic fertilizer crusher machines grind the material to a fine, consistent powder. This fine powder is essential for good granulation. Then comes the core granulation step.

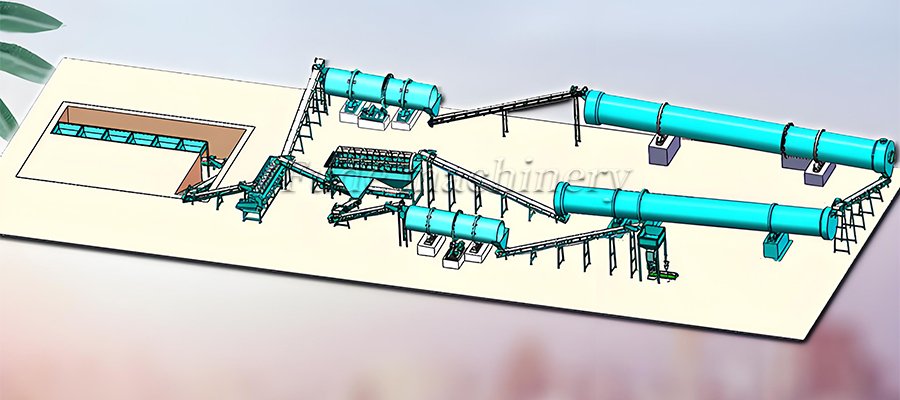

We have different granulators, like disc granulators, roller press granulators, and rotary drum granulators. These machines form the uniform pellets. Each of these pellets contains a balanced mix of nutrients. After granulation, our drying and cooling machines process the granules. This ensures they are stable and ready for storage. Finally, our screening and packaging machines prepare the final product for market. We can design and provide a complete organic fertilizer production line factory for you.

This covers every step from raw material to packaged granular product. We provide you with a one-stop solution for creating high-quality granular organic fertilizers.

For blended fertilizer production, our role is different but still important. Blended fertilizers involve mixing pre-existing granular components. We do not manufacture the large-scale blenders that physically mix the different granular components together. However, the individual granular components in a blended fertilizer can be produced using our equipment if they are organic-based.

For example, if you want to blend granular organic compost with other inorganic nutrients, our machines can make that organic granular component for you. Furthermore, our packaging machines are highly relevant for blended fertilizer operations. After the blending process, the mixed fertilizer needs to be accurately weighed and bagged. Our automatic packaging systems are perfect for this final step.

They ensure efficient and precise packaging. This means that while we specialize in creating the uniform granules, our equipment is still vital for the downstream processes of handling and packaging blended fertilizers. We help you with the crucial steps of preparing and packaging the materials.

Common Questions About Granular and Blended Fertilizer

Question 1: Can I use both granular and blended fertilizer together?

Yes, you can use both. Some farmers might use a custom blended fertilizer for general nutrient needs. They might then use a specific granular fertilizer for targeted micronutrient applications. It depends on your soil and crop requirements.

Question 2: Is one type of fertilizer more eco-friendly?

The eco-friendliness depends more on the raw materials than the form. Organic granular and organic blended fertilizers use organic waste. This is more eco-friendly than chemical fertilizers. Granular organic fertilizer production can be energy-intensive. But, it creates a stable, high-quality product.

Question 3: Does Fude Machinery only make machines for granular fertilizer?

My company primarily specializes in manufacturing equipment for granular organic fertilizer production. This includes all machines from composting to packaging. We also produce packaging and conveying systems. These can be used in blended fertilizer operations for handling the final mixed product. Our core expertise is in creating the uniform granules themselves.

Question 4: Which fertilizer type is better for precise application?

Granular fertilizer is generally better for precise application. Its uniform particle size leads to more consistent spreading. This helps ensure even nutrient distribution across the field. This uniformity minimizes nutrient hot spots or deficiencies.

Summary and Recommendations

Understanding the difference between granular fertilizer and blended fertilizer is important. Granular fertilizer is made by integrating all nutrients into each single pellet. This results in highly uniform products. They have less segregation risk. My company, Fude Machinery, specializes in the organic fertilizer equipment for making these types of granules. Blended fertilizer is a physical mixture of individual granular components. It offers high customization and lower production costs. But, it has a higher risk of nutrient segregation.

About Fude Machinery

We are Fude Machinery, a leading Chinese manufacturer of organic fertilizer equipment. Our base is in Zhengzhou. We focus on B2B solutions. We offer a full range of organic fertilizer equipment. This covers composting, crushing, granulation, drying, cooling, and packaging.

Contact Us

Do you want to learn more about fertilizer production? Are you ready to discuss your project? Contact our expert team today. We can help you design your ideal fertilizer solution. We will help you choose the right equipment.

Organic fertilizer equipment,organic fertilizer production line,organic fertilizer equipment factory

Organic fertilizer equipment,organic fertilizer production line,organic fertilizer equipment factory