In today’s competitive industrial world, improving productivity and product quality is the goal of every enterprise, and choosing an efficient and reliable disc granulator is an important step to achieve this goal.

To help more enterprises realize this leap in productivity, we offer a batch of high-performance disc granulators for pickup at our warehouse. Don’t miss the opportunity!

What is a disc pelletizer?

Disc granulator is a device that is widely used in chemical, pharmaceutical, for lubrication and other industries to convert powdered materials into granular materials, the main advantages of which lie in the high rate of particles, uniformity of particles and ease of operation, which makes it very suitable for large-scale production.

Advantages of disc granulator

- High productivity: The disc granulator adopts a special disc design, which ensures rapid mixing and granulation and greatly increases productivity.

- STABLE QUALITY: Through the precise control system, each batch of products has uniform granules and stable quality, which meets high standards.

- Energy-saving and environmentally friendly: Our disc granulators are energy-saving and environmentally friendly, reducing energy consumption and minimizing the impact on the environment.

- Easy Maintenance: Simple design and easy maintenance can reduce maintenance cost and prolong the service life of the equipment.

Why choose our warehouse?

- QUALITY ASSURANCE: All the disc pelletizers we offer undergo strict quality control to ensure the reliability of each unit.

- Fast Delivery: Our stock supply can shorten the delivery time and avoid delaying your production schedule.

- Personalized Service: Our professional technical team provides comprehensive after-sales support to solve any problems in time.

- Specials: Special warehouse sales discounts will save you money.

Organic fertilizer production line is a vital component in modern agriculture, which helps to achieve sustainable agricultural production. As people pay more attention to environmental protection and food safety, the use of organic fertilizer is becoming more and more popular.

Organic fertilizer production lines can convert various organic wastes into efficient and environmentally friendly fertilizers, reduce the use of chemical fertilizers, improve soil quality and promote plant growth.

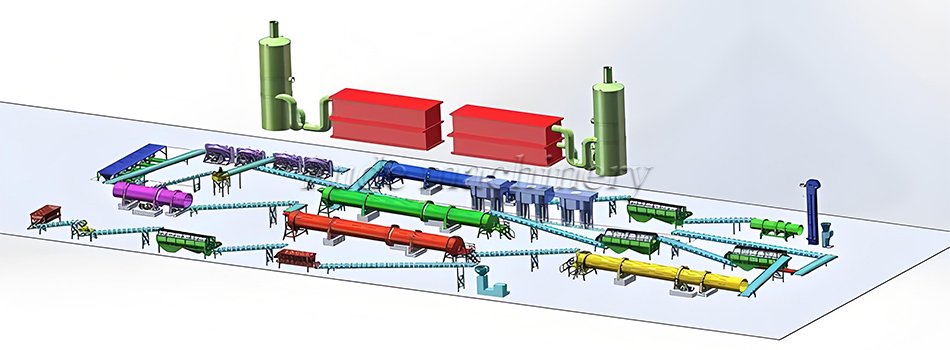

A typical organic fertilizer production line generally includes the following main links: raw material processing, fermentation, crushing, blending, granulation, drying, cooling, screening and packaging.

First, the production line starts with raw material processing. Various organic wastes, such as livestock and poultry manure, crop straw, food waste, etc., need pre-treatment to remove impurities and adjust the moisture content.

Next comes the fermentation stage, where the processed raw materials are stacked in fermentation equipment and the organic matter is fully decomposed at appropriate temperature and humidity by adding microbial strains and turning the pile regularly. This process usually takes several weeks and the fermented material is called compost.

After fermentation is complete, the materials need to be crushed and mixed. Grinding can improve the fineness of the materials and increase the uniformity of nutrients.

The purpose of blending is to fully combine materials and additives from different sources to achieve nutritional balance.

The next step is the granulation stage, where the crushed and blended materials are pressed into granules through a granulator.

The particle size can be adjusted according to demand and the granulated fertilizers are easy to transport, apply and store. After granulation, granular fertilizers generally need to be dried and cooled to reduce moisture content and increase product stability and shelf life.

Finally, the dried and cooled granular fertilizer must be sieved to ensure that the particle size is uniform and meets product specifications. Qualified particles enter the packaging stage and eventually become organic fertilizer products sold in the market.

The use of organic fertilizer production lines can not only effectively treat various kinds of organic wastes and reduce environmental pollution, but also provide a source of high quality fertilizer for agricultural production, promoting green circulation and sustainable agricultural development.

In the future, with the continuous advancement of technology and the improvement of environmental awareness, organic fertilizer production lines will play a more important role.

Act now to support your business growth

Choosing the right disc granulator not only improves performance, but also brings great economic benefits. If you’re looking for efficient production equipment, there’s never been a better time. We have limited stock at Fude Machinery, so contact our sales team today for more information and advice.

Organic fertilizer equipment,organic fertilizer production line,organic fertilizer equipment factory

Organic fertilizer equipment,organic fertilizer production line,organic fertilizer equipment factory