In the burgeoning realm of sustainable agriculture, bio organic fertilizers have emerged as a cornerstone for eco – friendly farming. To meet the rising demand, our state – of – the – art bio organic fertilizer making system is now available for sale, designed to streamline production while ensuring top – notch product quality.

Our bio organic fertilizer production line is a modular and scalable system. It can handle diverse raw materials like livestock manure, crop residues, and food waste, catering to different production capacities. With a production range from 1 – 5 tons per hour, it suits both small – scale enterprises aiming for local markets and medium – sized manufacturers targeting broader distribution. The line integrates advanced technology with user – friendly operation, making it accessible for various levels of expertise.

Raw Material Pretreatment

The organic biofertilizer production process starts with pretreatment equipment. Crushers reduce large – sized raw materials into manageable pieces, while mixers blend them with necessary additives for a balanced nutrient composition. Screening machines eliminate impurities, ensuring only high – quality materials move to the next stage.

Fermentation Unit

Fermentation is crucial for bio organic fertilizer production. Our line features efficient fermentation tanks or turners. These control temperature, humidity, and oxygen levels precisely, facilitating the growth of beneficial microorganisms. This process decomposes organic matter, converting it into nutrient – rich, stable fertilizer within 7 – 14 days.

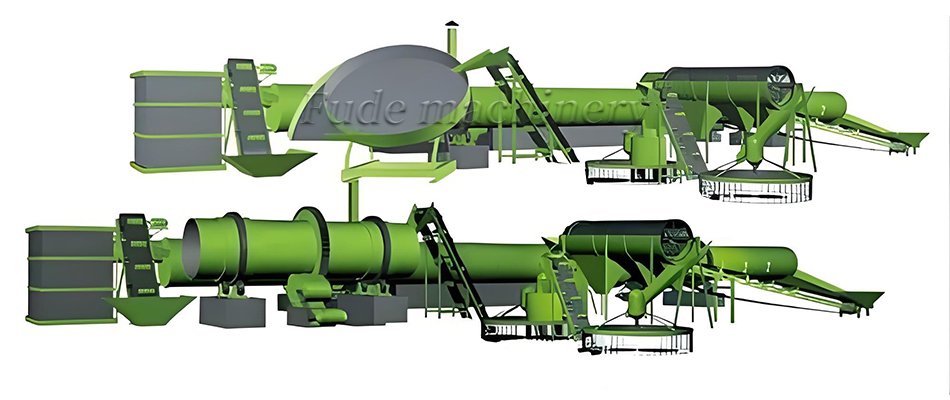

Granulation System

We offer two main granulation options: drum granulators and disc granulators. Drum granulators create granules through a rotating drum, ideal for high – volume production with a wide size range. Disc granulators, on the other hand, produce more spherical and uniform granules, suitable for premium products.

Drying and Cooling

After granulation, rotary dryers remove excess moisture, enhancing storage stability. Subsequently, cooling systems bring the granules to an optimal temperature, preventing caking and preserving their physical properties.

Packaging Equipment

Automatic packaging machines handle the final step. They accurately weigh, fill, and seal fertilizers into bags of various sizes, from 5 kg retail packs to 50 kg bulk bags, ensuring products are market – ready.

First, raw materials are collected and pretreated. Then, they enter the fermentation unit for decomposition. Once fermented, the materials are granulated, followed by drying and cooling. Finally, the finished product is packaged and prepared for distribution. Each step is monitored for quality control, ensuring consistent output.

Our production line offers high – efficiency, reducing production time by up to 30% compared to traditional methods. It also minimizes energy consumption, with the fermentation process recycling heat and drying units using energy – saving technologies. The line adheres to strict environmental standards, reducing waste and emissions. Moreover, its automation reduces labor costs and human error, guaranteeing reliable operation. Click here to get more!

When you purchase our Fude Machinery line, you get comprehensive support. Our sales team provides customized solutions based on your requirements. Post – sale, we offer installation, operator training, and regular maintenance services. A 24/7 technical support hotline ensures quick resolution of any issues, maximizing your production uptime.

In conclusion, our bio organic fertilizer production line for sale is a reliable investment for those looking to enter or expand in the bio organic fertilizer market. With its advanced features, efficient operation, and excellent support, it’s poised to drive your business forward. Contact us today to learn more!

Organic fertilizer equipment,organic fertilizer production line,organic fertilizer equipment factory

Organic fertilizer equipment,organic fertilizer production line,organic fertilizer equipment factory