In the ever-growing organic farming industry, efficient fertilizer production is crucial. A key player in this process is the Disc Granulator, an essential machine for converting powdered organic fertilizers into high-quality spherical granules.

Compared to powdered fertilizers, granules offer advantages in terms of transport and storage. But how exactly does this machine work?

Table of Contents

How does the Disc Granulator work?

The disc granulator operates on a simple but effective principle. Driven by a motor, it rotates a disc in which organic materials are added.

These materials are then mixed with water and agglutinated into spherical granules by centrifugal motion. The granulator design includes an automatic cleaning device to prevent material build-up, ensuring longer machine life.

Why Choose a Disc Granulator?

- Cost-Effective Production: This technology can reduce production costs by up to 30%, making it an attractive option for fertilizer manufacturers looking to optimize their operations.

- Versatile Material Handling: Whether animal manure, metals or minerals, the Disc Granulator can process a wide variety of raw materials, providing flexibility for diverse production needs.

- Durability and Long Lifetime: Manufactured with high quality materials such as carbon steel, the machine ensures longevity and low maintenance costs.

Advantages of disc granulator

Disc pelletizer has significant advantages. Good balling performance, high balling rate, can efficiently gather the material into balls, reduce the waste of raw materials, and good particle uniformity, conducive to the storage and transportation of fertilizers and crop nutrient absorption;

Easy to operate and maintain, simple structure, the operator can be started after simple training, and daily maintenance is also easy, such as the replacement of worn out lining plate without the need for complex tools and professionals;

Adaptability and flexibility, can deal with a variety of organic fertilizers raw materials, but also flexible adjustment of parameters and production capacity according to market demand and production scale; cost and environmental protection advantages are outstanding.

Adaptability and flexibility, can handle a variety of organic fertilizer raw materials, but also according to market demand and production scale flexible adjustment of parameters and production capacity;

Cost and environmental protection advantages, low cost of equipment, suitable for small enterprises, and less production dust, can realize the resource utilization of waste, reduce environmental pollution.

What are the applications of disc granulators?

Disc granulator has a wide range of applications, in the organic fertilizer industry, can be livestock and poultry manure, crop residues, urban sludge, etc. made of granular fertilizer, easy to store and transport and improve the utilization rate;

In the compound fertilizer industry, the production of nitrogen, phosphorus and potassium composite fertilizers and organic – inorganic compound fertilizers with different ratios;

In the chemical industry, used for catalysts, pigment granulation, to improve its performance;

In the feed industry, can be made into particles of pet feed and aquatic feed raw materials to meet the needs of different animal consumption, such as the production of round pellets for cats and sinking aquatic pellet feed.

In the feed industry, it can make the pet feed and aquatic feed raw materials into granules to meet the needs of different animals, such as the production of round pellets for cats and sinking aquatic pellets.

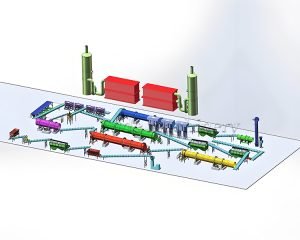

What is Needed for a Complete Production Line?

To take full advantage of the power of the Disc Granulator, it must be part of a complete fertilizer production line. This includes crushers, automatic dosers, mixers and dryers, among others. With the right equipment in place, continuous and efficient production of organic fertilizer granules is guaranteed.

Disc granulator complete production line process is: first of all, livestock and poultry manure and other raw materials for fermentation, removal of impurities and crushing, and then according to the formula of organic raw materials and auxiliary materials and mix and add water to the appropriate humidity, and then the material through the spiral feed into the disc granulator, rotating tilted by the disc molded into particles, after the particles in turn by drying to remove moisture, cooling to reduce the temperature in order to prevent agglomeration.

And then sieving to remove the particles of unqualified ( After that, the particles are sieved to remove unqualified particles (the unqualified ones are crushed and returned to the granulation system), and the qualified particles are coated with film to enhance the brightness and roundness, and finally, they are bagged with automatic packaging machine for identification and proper storage.

Advantages of a complete production line

The complete production line has significant advantages. Raw material processing by fermentation, removal of impurities and crushing, not only to remove odor, decomposition of crude fiber, but also to ensure uniformity of raw material particle size, laying a good foundation for the subsequent granulation; wet preparation of accurate ratio and control of humidity, so that the nutrients are evenly distributed to improve the quality of fertilizer.

Disc pelletizing link utilizes the characteristics of disc to form balls efficiently, with high rate of ball formation and good uniformity of particles, which reduces the waste of raw materials and facilitates the absorption of crops. Subsequent drying, cooling, sieving and other links work closely together to remove moisture, prevent caking and separate unqualified particles to ensure product qualification rate and stability.

Finished products are coated to increase the brightness and roundness of the particles, which improves the product appearance and market competitiveness. Finally, the automatic packaging and storage improves the production efficiency and guarantees the long-term quality of the products, realizing the efficient and high-quality transformation from raw materials to finished products.

If you are looking to optimize the production of organic fertilizers, the Disc Granulator is a must-have machine. Its cost-effectiveness, versatility and durability make it an excellent choice for companies looking to improve their operations.

For more information and to explore other related equipment, check out our full range of organic fertilizer production solutions here.

Organic fertilizer equipment,organic fertilizer production line,organic fertilizer equipment factory

Organic fertilizer equipment,organic fertilizer production line,organic fertilizer equipment factory