Smart investment: do factors affect the price of compost pellet mills?

156In the realm of sustainable agriculture and waste management, compost pelleting machines have carved out an essential niche.

View detailsSearch the whole station

I often talk to clients about granulation. They hear about different machines. A common question is about the disc pelletizer. People ask, “What is it exactly?” They also want to know, “Is it complicated to work with?” These are very good questions. The disc pelletizer is a core piece of equipment for making organic fertilizer pellets. It plays a big role in creating high-quality granules. Understanding how it works is important. Knowing its operation helps you decide if it is right for your business. I will explain what a disc pelletizer is. I will also tell you if it is complicated to work with. My company, Fude Machinery, provides these machines. We also offer training to make them easy for you to use.

Last Updated: June 2025 | Estimated Reading Time: 15 minutes

This article will help you understand:

A disc pelletizer, also known as a disc granulator, is a machine that turns powdery materials into round, uniform pellets or granules. In the organic fertilizer industry, it is a very popular choice. It takes finely crushed organic materials. It then forms them into small, easy-to-handle fertilizer pellets. These pellets are much better than loose powder. They are easier to store. They are easier to transport. They are also easier to apply to fields. This machine is key for producing high-quality granular organic fertilizer.

The main job of a disc pelletizer is to create a specific product form. It changes a fine powder into solid, spherical particles. This process is called wet granulation. It means adding a liquid, like water or a binder solution, to the powder. This liquid helps the powder particles stick together. The disc pelletizer ensures that each pellet has a consistent size and shape. This uniformity is very important for the final fertilizer product. It ensures even nutrient distribution when applied. It also helps the product flow smoothly through spreading equipment. My company provides various organic fertilizer equipment . The disc granulator is a key part of our granulation system.

This machine works continuously. You feed the raw material into it. The pellets form and grow. They then roll off the disc when they reach the right size. This continuous operation makes it very efficient. It is used in many industries. But, it is especially valuable for organic fertilizer production. It transforms waste materials into valuable products. This adds significant value to your organic fertilizer business. It helps you meet the demand for high-quality organic fertilizers. It also helps you produce an appealing product for the market.

The operation of a disc pelletizer is based on simple physical principles. It looks complex. But, its core working mechanism is straightforward. Understanding this helps you use it effectively.

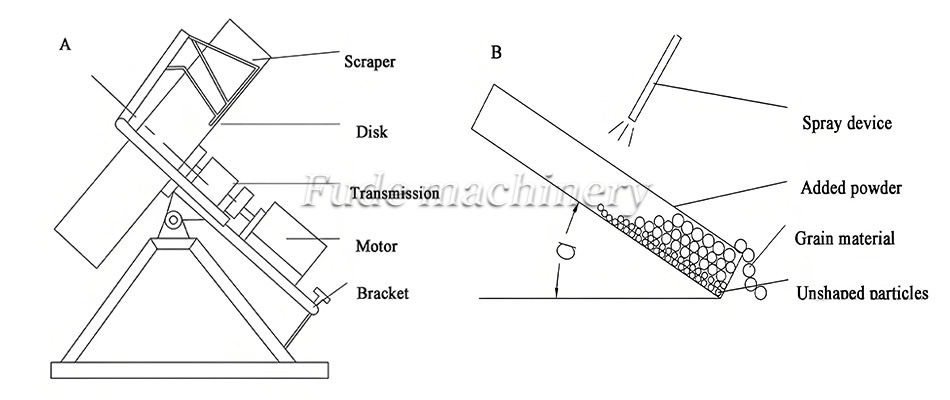

The process starts when you feed finely processed organic powder onto the rotating disc. This powder is usually pre-mixed with other ingredients. These ingredients might include binding agents or nutrient additives. The disc is angled. It rotates at a controlled speed. This rotation creates a tumbling motion for the material. As the material tumbles, a spray system adds a fine mist of water or a liquid binder. This liquid makes the dry particles slightly sticky.

Recommended Image Filename: how-disc-pelletizer-works.jpg

Tiny particles start to stick together. They form small “seed” pellets. As these seed pellets roll around on the disc, they pick up more dry material. They also pick up more liquid. This process is like making a snowball. As the snowball rolls, it gets bigger. The pellets grow layer by layer. The constant tumbling motion makes them round and dense. The angle of the disc and its rotation speed are key. They control how fast the pellets grow. They also control the final size of the pellets.

Once the pellets reach a certain size and weight, they roll over the edge of the disc. Gravity helps them fall off. They then go to the next stage of processing. This next stage might be drying or cooling. A scraper blade helps prevent material from sticking to the disc surface. It also helps keep the material moving. This entire process is continuous. It allows for high production volumes. This systematic approach ensures uniform pellet size and shape. It helps produce consistent, high-quality organic fertilizer.

A disc pelletizer has several main parts. Each part plays a crucial role in the granulation process. Understanding these components helps you understand the machine better. It also helps with maintenance.

These components work together seamlessly. They transform raw organic powder into high-quality fertilizer pellets. My company ensures that all these components are robust. They are also made from high-quality materials. This ensures durability and efficient performance for your organic fertilizer production.

Many people worry about operating new machinery. They think it might be complicated. For a disc pelletizer, the answer is no, it is generally not overly complicated to work with, especially with modern designs and proper training. It has some critical adjustments. But, once you understand them, the daily operation becomes routine.

The main aspects to control are:

These three factors are interconnected. They need to be balanced. For example, if you add too much water, the pellets become too sticky. If you add too little, they will not form. Adjusting these settings during the initial setup is the most challenging part. This process requires some experience. It requires careful observation. However, modern disc pelletizers often have automated control systems. These systems make the operation much simpler. They can monitor and adjust these parameters for you. This reduces the need for constant manual intervention.

My company provides full-service support. This includes installation and debugging. Our engineers help set up the machine. They make the initial adjustments. We also offer personnel training. We teach your operators how to use the machine correctly. We show them how to adjust the settings. We also teach them how to troubleshoot common issues. This training is very important. It empowers your team. It makes them confident in operating the equipment.

Maintenance is also straightforward with modern designs. Regular cleaning of the disc and scraper is needed. Checking for wear on parts is also important. Our machines are built with durability in mind. This reduces the need for frequent complex repairs. So, while there is a learning curve, it is manageable. With Fude Machinery’s support, your team can quickly become proficient in operating the disc pelletizer. It will become a reliable part of your organic fertilizer production line .

Using a disc pelletizer offers many benefits for organic fertilizer production. These benefits contribute to higher product quality. They also lead to better market appeal. They improve your overall operational efficiency.

These benefits make the disc pelletizer a very valuable machine. It helps you create high-quality organic fertilizer. It boosts your product’s market value. It contributes to a more efficient and profitable operation. My company can help you leverage these benefits. We provide robust and efficient disc granulators for your business.

The technology behind disc pelletizers is always advancing. New trends aim to make these machines even more efficient. They also aim to make them easier to use. Staying updated on these trends helps you make smart investment decisions.

Enhanced Automation and Smart Controls: This is a major trend. New disc pelletizers come with advanced sensors. They have sophisticated control systems. These systems monitor critical parameters. They include moisture content. They also include disc speed. They automatically adjust settings. This optimizes the granulation process. It reduces the need for manual adjustments. It improves consistency. It also reduces labor costs for you. This makes the machine much less complicated to work with.

Latest Progress:

Improved Energy Efficiency: Manufacturers are focusing on reducing energy consumption. They design motors and drive systems that use less power. They also optimize the disc and scraper designs. This minimizes friction. It makes the granulation process more energy-efficient. This reduces your operating costs. It also makes your production more sustainable.

Wear-Resistant Materials and Longer Lifespan: Equipment is being built with more durable materials. This extends the machine’s lifespan. It reduces the need for frequent part replacements. This lowers maintenance costs for you. It also increases uptime. This means your machine runs longer without interruptions. This focus on durability makes the investment more worthwhile.

Modular Design for Customization: Newer disc pelletizers offer modular designs. This means you can easily add or change components. You can customize the machine to fit specific raw materials. You can also customize it for different product requirements. This flexibility helps your business adapt to changing market demands. It ensures your equipment remains relevant for a long time.

These trends aim to make disc pelletizers more reliable. They also aim to make them more productive. They are also easier to integrate into modern organic fertilizer plants. This ensures that operating them becomes even less complicated in the future.

Question 1: What kind of materials can a disc pelletizer process?

A disc pelletizer can process various organic materials. This includes animal manure, composted agricultural waste, sludge, and some industrial organic residues. It works best with finely ground powders that can be wetted and agglomerated.

Question 2: Does a disc pelletizer need a dryer after it?

Yes, usually it does. Disc pelletizers use wet granulation. This means the pellets contain moisture. You usually need a rotary dryer to reduce the moisture content. This makes the pellets stable for storage and prevents caking.

Question 3: How do I control the size of the pellets?

You control pellet size by adjusting several parameters. These include the angle of the disc, its rotation speed, the amount of raw material feed, and the rate of liquid spray. Proper balancing of these factors helps achieve the desired granule size.

Question 4: What are the main benefits of spherical pellets from a disc pelletizer?

Spherical pellets offer superior flowability. They are easier to spread uniformly. They have better aesthetic appeal. They are also more durable during handling and transport. These qualities make them highly desirable in the market.

The disc pelletizer is a vital machine for organic fertilizer production. It transforms loose organic powder into uniform, spherical pellets. This process is important. It improves product handling, storage, and application. It also enhances nutrient efficiency. It reduces environmental impact. It significantly increases your product’s market value.

Working with a disc pelletizer is generally not complicated. Modern machines have advanced controls. My company provides comprehensive training and support. This helps your team operate them effectively. When choosing a disc pelletizer, consider your raw materials, desired capacity, granule needs, budget, and the level of automation you prefer.

I recommend investing in a high-quality disc pelletizer. This decision will boost your product quality and operational efficiency. Partner with a reliable manufacturer like Fude Machinery. We can provide you with robust equipment. We also offer full-service support. This helps ensure your success in the organic fertilizer market.

We are Fude Machinery, a leading Chinese manufacturer of organic fertilizer equipment. Our base is in Zhengzhou. We focus on B2B solutions. We offer a full range of organic fertilizer equipment. This covers composting, crushing, granulation, drying, cooling, and packaging. We also design complete production lines. Our facilities are well-equipped. We have strict quality control. We have exported our products to over 120 countries. Our team of 15 technical engineers ensures top-quality design and production for you.

Do you want to learn more about disc pelletizers? Are you ready to optimize your organic fertilizer granulation process? Contact our expert team today. We can help you choose the right equipment. We will ensure your production is efficient and profitable.

Last Updated: June 2025

In the realm of sustainable agriculture and waste management, compost pelleting machines have carved out an essential niche.

View detailsPlan your phosphate fertilizer granulation production line.

View detailsProcessing pomace, a high-moisture organic waste, into organic fertilizer presents significant opportunities for industries like wineries, cider mills, and juicing facilities.

View detailsThe Charcoal-based Fertilizer Disc Granulator is a machine designed for the granulation of charcoal-based fertilizers.

View details