Can you revolutionize agriculture with charcoal-based fertilizer lines?

96A powdered carbon-based fertilizer production line is a comprehensive system designed to produce fine

View detailsSearch the whole station

I frequently receive questions about organic fertilizer, particularly why granulating it is crucial and how to select suitable equipment. Granulation significantly enhances fertilizer quality, making it user-friendly and more valuable. Choosing the right granulation gear is vital for product quality and production efficiency. I’ll elucidate the importance of organic fertilizer pellet production for your business and offer guidance on selecting optimal equipment. Fude Machinery specializes in providing tailored solutions for you.

Last Updated: June 2025 | Estimated Reading Time: 15 minutes

Recommended Image Filename: organic-fertilizer-pellet-importance-equipment.jpg

This article will help you understand:

Organic fertilizer pellet production is crucial as it upgrades raw organic materials into a high-value, marketable, and farmer-friendly product. Without pelletizing, organic fertilizer remains loose, dusty, and hard to handle. Pelletization creates stable, uniform pellets from various organic wastes like animal manure or crop residues, making them easy to transport, store, and apply. Farmers prefer pellets for their compatibility with standard spreading equipment, saving time and labor, and ensuring even nutrient distribution for consistent crop growth and better yields.

Environmentally, pellet production addresses pollution, odors, and water contamination risks from raw organic waste. It stabilizes organic matter, reduces odors, and prevents nutrient leaching into groundwater, promoting sustainability and compliance with regulations. Additionally, pelletizing sterilizes the material, removing pathogens and weed seeds, enhancing safety for food crops. These benefits underscore the importance of pellet production for modern organic fertilizer companies, improving product quality, usability, and environmental impact.

Pellets greatly simplify handling and storage for farmers and distributors. Unlike bulky, dusty loose organic fertilizer, pellets are dense and uniform, occupying less space, being easier to stack, and reducing shipping costs. Their solid form prevents dusting, creating a cleaner, safer work environment. Pellets flow smoothly through spreading equipment, minimizing clogging and enhancing application efficiency.

Their increased bulk density is a significant benefit. Loose compost is lightweight and hard to move in large volumes, but pelletizing compacts the material, allowing more fertilizer per bag or container and more product storage in the same space, cutting storage costs and improving logistics. Pellets also resist moisture absorption during storage, preventing caking, maintaining free-flowing properties, and extending shelf life, making the product more reliable for customers.

Pellets significantly improve nutrient release and efficiency in soil, a key benefit for farmers. Raw organic matter decomposes unevenly, causing inconsistent nutrient availability. Pellets offer a controlled, uniform nutrient release, ensuring plants receive a steady nutrient supply over time. Each pellet contains a balanced mix of nitrogen, phosphorus, potassium, and micronutrients, spreading evenly across fields for consistent crop growth and maximum nutrient uptake.

The compact pellet form enables slow nutrient release, preventing immediate breakdown and gradual dissolution to reduce leaching or volatilization losses. This boosts fertilizer efficiency, cuts costs, and minimizes environmental pollution from runoff. Uniform pellet size ensures even field distribution, avoiding nutrient “hot spots” or “cold spots,” and fostering healthier, more productive crops, leading to better yields and higher profits for farmers.

Pellet production cuts the environmental impact and odor of organic waste, particularly animal manure, which emits strong smells and can pollute water and air. Pelletizing stabilizes materials, locking in volatile compounds to reduce odors, making handling and storage more pleasant and aiding compliance with environmental regulations.

The process often includes high-temperature drying, killing harmful pathogens and weed seeds, enhancing fertilizer safety for the environment and crops. By converting waste into a stable product, pelletizing prevents soil and water contamination, minimizing harmful runoff and fostering healthier ecosystems. This demonstrates your company’s sustainability commitment. Our organic fertilizer equipment enables waste transformation into a valuable, eco-friendly product, helping you build a responsible and respected business.

Pellet production directly increases the market value and appeal of your organic fertilizer. Unprocessed organic material looks less appealing. It is hard to distinguish its quality. Pellets have a clean, professional appearance. They are uniform in size and shape. This makes them look like a premium product. This professional appearance helps you stand out in the market. It allows you to command higher prices. Consumers, including farmers and distributors, are more willing to buy a product that looks good and is easy to use.

The ease of use is another major selling point. Farmers want products that save them time and effort. Pellets flow easily through spreaders. They store well. They cause less dust. These practical advantages make them highly attractive. The reputation for consistent quality that comes with pelletized organic fertilizer builds trust. This trust leads to repeat business. It helps you grow your customer base. Our comprehensive organic fertilizer production line ensures high-quality pellets. This helps you maximize your product’s market potential. It helps you build a strong brand reputation.

Selecting the right granulation equipment is crucial for your organic fertilizer company, as it’s a significant investment affecting production efficiency and product quality. Here are key considerations to guide your choice:

Desired Output Capacity: Your production goals determine the granulator size. Small farms may need a few tons per day, while large commercial producers might require hundreds. Overestimating leads to overspending on an oversized machine; underestimating causes bottlenecks. Our company offers models with varying capacities to match your production scale and can help design a complete production line tailored to your output needs, ensuring a balanced and efficient system.

Raw Materials: The type and characteristics of your raw materials are paramount. Different granulators suit different materials. For high-moisture content like fresh animal manure, disc or rotary drum granulators work well, using water or binders. For drier, fine powders like composted straw, a roller press granulator is ideal, requiring no added moisture. Material composition also matters—stickiness, abrasiveness, and particle size post-crushing influence granulator selection. Our crushers can prepare various materials, and a stirring tooth granulator may be suitable for materials needing intense mixing.

Granule Shape and Size:Desired granule shape and size influence granulator selection. Disc and rotary drum granulators typically produce spherical pellets, favored for uniform spreading and aesthetics. Roller press granulators yield irregular or pillow-shaped granules that may require polishing. Pellet size can often be adjusted. Aligning your market’s preferences with granulator capabilities ensures your product meets customer expectations and works with standard spreading equipment.

Budget and Investment Plan:Budget and investment planning are critical. Granulation equipment costs vary by type, capacity, automation, and features. Balance initial costs with long-term benefits—cheaper machines may have higher operating or maintenance costs, while efficient, expensive ones may offer quicker ROI. Consider supporting equipment costs, such as crushers, dryers, and packaging machines. Our factory-direct sales and full-service support provide cost advantages and protect your investment.

Automation and Efficiency:Automation level and energy efficiency impact your choice. Automated systems reduce labor costs, enhance production consistency, and minimize errors, though they require higher initial investment. Energy-efficient machines lower long-term operational expenses. Our equipment emphasizes high efficiency and energy savings. Decide if the upfront cost of an automated, energy-efficient system aligns with your business goals, labor availability, and long-term savings.

After-sales service and support:After-sales service and support are crucial. Equipment can fail, requiring spare parts or technical help. A reliable supplier offers comprehensive support, including installation, debugging, staff training, and maintenance. Poor support leads to costly downtime and production interruptions.

Our company provides full-service support with professional technical teams for timely assistance, minimizing operational risks and protecting your investment. Choosing a supplier committed to after-sales service is as vital as selecting the equipment, ensuring your long-term success.

My company, Fude Machinery, offers a variety of granulation equipment. Each type has its unique advantages. Understanding these helps you make the best choice for your specific organic fertilizer production. We ensure high quality and efficient performance for all our machines.

A disc granulator uses wet granulation, with a rotating disc set at an angle. Raw material powder is fed onto the disc, and water or a binder is sprayed. As the disc rotates, the material tumbles, forming larger, spherical granules layer by layer. The disc’s speed and angle control granule size. Ideal for moist materials, it produces uniform, round pellets with good appearance and flowability, enhancing marketability.

How Does a Roller Press Granulator Benefit Your Business?

A roller press granulator employs dry granulation, suitable for heat-sensitive or very dry materials. Two counter-rotating rollers press the material into dense flakes, which are then crushed into granules. This method skips drying, saving energy and reducing costs. The granules are dense and strong, though they may need polishing for perfect roundness. It’s excellent for high-density, dust-free products.

How Does a Rotary Drum Granulator Suit Your Needs?

A rotary drum granulator uses wet granulation in a long, rotating cylindrical drum. Raw materials and binders are fed in, and as the drum rotates, particles agglomerate into granules. Known for large capacity and uniform granules, it’s ideal for high-volume production lines, handling various materials and suitable for compound fertilizers. Its robust design ensures continuous operation and high output.

How Does a Stirring Tooth Granulator Work?

A stirring tooth granulator combines mixing and granulation in one step, with high-speed stirring teeth inside a drum. Raw material is rapidly mixed, causing particles to collide and stick together, forming granules. Ideal for fine powdery materials, it simplifies production and is compact. Granules may be less perfectly round than those from a disc granulator, but it offers a cost-effective granulation solution.

TThe organic fertilizer industry is evolving, with new technologies and practices emerging. Staying current with trends in efficiency, quality, and environmental responsibility is key to remaining competitive. Here are key trends shaping organic fertilizer pellet production in 2025:

These trends highlight a shift towards more intelligent, sustainable, and adaptable production systems. Investing in equipment that aligns with these trends will position your company for long-term success.

Question 1: Is organic fertilizer pellet production profitable?

Yes, it can be very profitable. Pelletizing adds significant value to organic waste. It improves usability. It increases market appeal. This allows you to sell at a higher price. It also reduces handling and transportation costs.

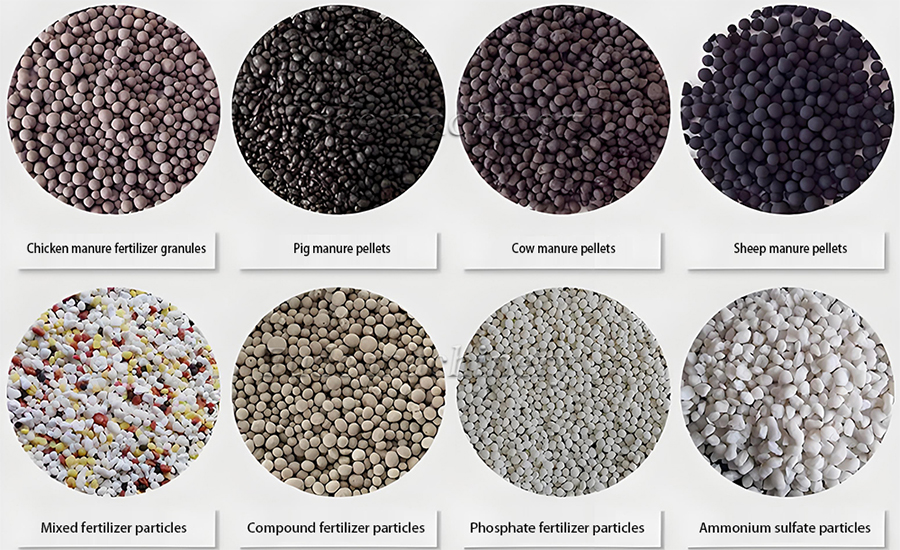

Question 2: What are the main types of raw materials for organic fertilizer pellets?

Common raw materials include various types of animal manure (chicken, cow, pig), crop residues (straw, rice husks), municipal sludge, food waste, and industrial organic waste.

Question 3: How does the moisture content affect granulation?

Moisture content is critical. Too little moisture can prevent pellet formation. Too much moisture can make pellets sticky or easily deformable. Different granulators require different optimal moisture levels for efficient operation.

Question 4: What is the typical lifespan of granulation equipment?

The lifespan of granulation equipment depends on its quality, maintenance, and usage. High-quality machines, like those from Fude Machinery, can last 10-15 years or even longer with proper care and regular maintenance.

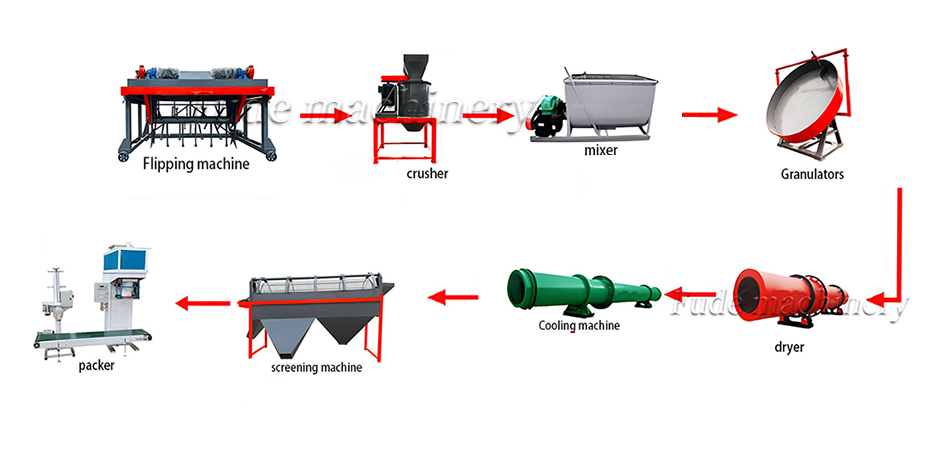

Organic fertilizer pellet production is crucial for your business. It transforms raw organic waste into a valuable, easy-to-use, and environmentally friendly product. Pelletizing improves handling, storage, and nutrient efficiency. It reduces odors and pollution. It also significantly increases your product’s market value. Choosing the right granulation equipment is essential for success. You must consider your raw materials, desired capacity, granule characteristics, budget, automation needs, and supplier support.

I recommend that you carefully assess all these factors. Then, choose a granulation solution that aligns with your specific production goals and long-term vision. Investing in high-quality, efficient equipment will pay dividends. It leads to lower operating costs and a superior product. Partner with a reliable manufacturer like Fude Machinery. We can provide you with comprehensive solutions and expert support.

We are Fude Machinery, a leading Chinese manufacturer of organic fertilizer equipment. Our base is in Zhengzhou. We focus on B2B solutions. We offer a full range of organic fertilizer equipment. This covers composting, crushing, granulation, drying, cooling, and packaging. We also design complete production lines. Our facilities are well-equipped. We have strict quality control. We have exported our products to over 120 countries. Our team of 15 technical engineers ensures top-quality design and production for you.

Do you want to discuss your organic fertilizer pellet production needs? Are you ready to choose the right granulation equipment? Contact our expert team today. We can help you design the most efficient and profitable solution for your business.

Last Updated: June 2025

A powdered carbon-based fertilizer production line is a comprehensive system designed to produce fine

View detailsBentonite granules, often used in organic fertilizers, improve soil structure, increase water retention, and promote overall plant health.

View detailsThe disc pelletizer is a core piece of equipment for making organic fertilizer pellets.

View detailsWith accelerating urbanization and population growth, the amount of sludge produced in wastewater treatment plants continues to increase.

View details