How to choose the right fertilizer production line

In agriculture, the quality and efficiency of fertilizer use have a direct impact on yields and product quality. To ensure efficient fertilizer production and meet market demand, it is critical to choose the right production line. So, how do you choose a fertilizer production line that is right for you? In this article, we look at the key factors that will help you make an informed decision.

Determine your production needs

Before selecting a production line, it is important to clearly define your specific production needs, including:

- Production scale: is a small line or a large industrial line required?

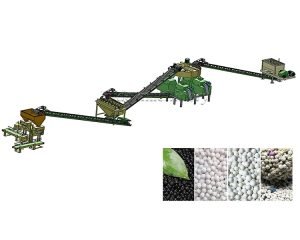

- Fertilizer type: will it be compound fertilizer, organic fertilizer or mixed fertilizer production?

- Raw material source: which raw materials will be used? Will special processes be required?

Understanding this basic information will help you determine the specifications and types of equipment required.

Consider the production process

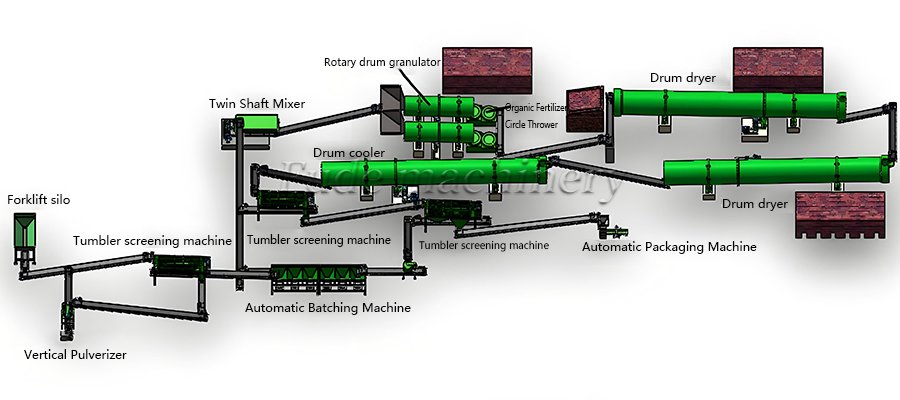

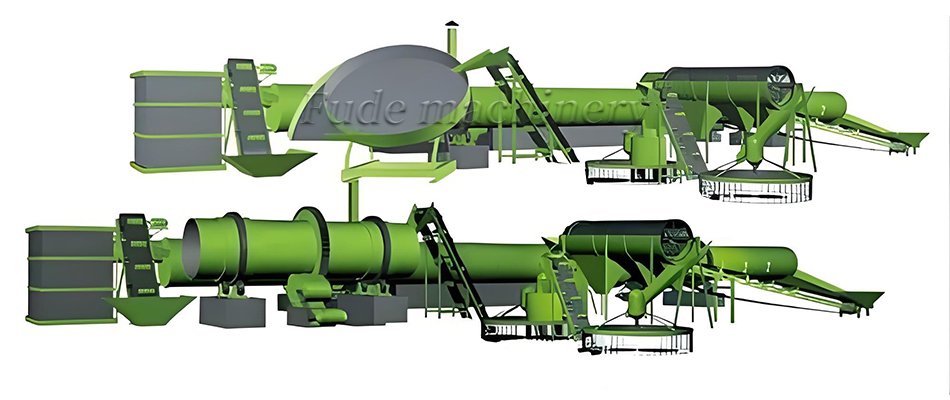

Different types of fertilizer production lines involve different processes. Understanding the process will help you choose the right equipment configuration. Basic process flows include:

- Granulation: e.g. disk granulation, drum granulation, etc.

- Mixing: ensuring uniform mixing of the various components.

- Drying and cooling: reducing the moisture content of the finished fertilizer.

- Screening and packaging: ensuring product uniformity and ease of transportation and storage.

Equipment quality and supplier reputation

Choosing a supplier with a good reputation and high quality equipment is very important. You can evaluate a supplier in the following ways:

- Read testimonials and case studies: read other customers’ experiences and success stories.

- Visit the production line: inspect the supplier’s production line to see the performance and quality of the equipment.

- After-sales service: good after-sales service can ensure the stable operation of the equipment for a long time and reduce maintenance costs.

Profitability analysis

When selecting a fertilizer production line, consider not only the initial investment in the equipment, but also the long-term operating and maintenance costs. Conduct a comprehensive profitability analysis including:

- Equipment acquisition costs: offers from different suppliers.

- Operating costs: energy consumption, labor costs, etc.

- Maintenance and repair costs: durability of the equipment and frequency of repairs.

Environmental impact and regulatory compliance

When selecting a fertilizer production line, also consider its environmental impact and compliance with local environmental regulations. Ensure that the design of the production line complies with environmental standards and reduces emissions of gases, wastewater and solid waste.

Choosing the right fertilizer production line requires a comprehensive consideration of production needs, process requirements, equipment quality, profitability and environmental impact. By conducting a thorough analysis and making an informed decision, you can select an efficient, cost-effective and environmentally friendly production line to improve product quality and competitiveness in the market. We hope this guide will help you make the best decision when choosing fertilizer production equipment and achieve long-term business growth and sustainability. For more information,Please consult us at Fude Machinery!

Organic fertilizer equipment,organic fertilizer production line,organic fertilizer equipment factory

Organic fertilizer equipment,organic fertilizer production line,organic fertilizer equipment factory