What machines are used to make dog food?

235The machine used to make dog food is usually called Feed puffing machine or pet food processing equipment

View detailsSearch the whole station

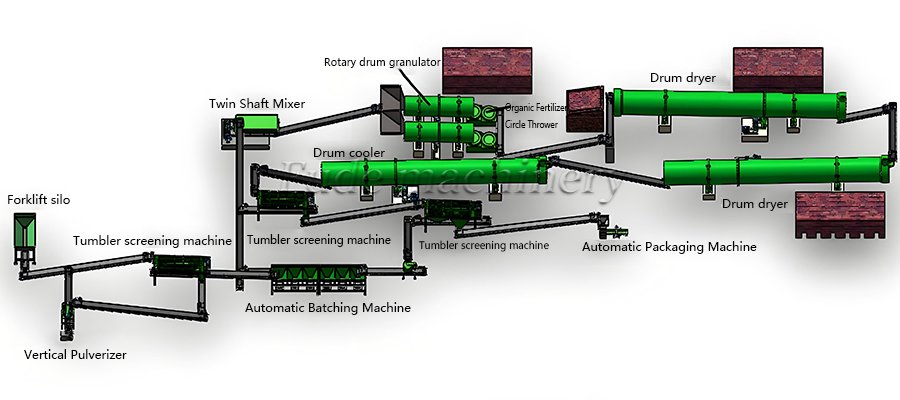

As an efficient granule making equipment, the drum pelletizer occupies an important position in the fertilizer industry. Its unique design and excellent performance make

rotary drum pellet machine

an indispensable part of fertilizer production process. This article will discuss in detail the working principle, technical advantages and application of drum pelletizer in fertilizer industry.

The central component of the rotary drum pellet mill is a large horizontal cylinder, usually called a drum. Material enters the drum through the feed port. As the drum rotates, the material rises and falls continuously into the drum. This cyclic rolling motion causes friction and collision between materials, thus gradually forming particles. During the granulation process, a certain amount of liquid or binder is usually added to improve material adhesion and particle strength.

rotary drum pellet machine design allows it to handle large quantities of materials and is suitable for large-scale production needs. Its high productivity is one of the main reasons for choosing this equipment in fertilizer industry. Good particle uniformity: by adjusting the rotation speed, the angle of inclination and the internal structure of the drum, particles with uniform particle size can be produced. This uniformity is critical to the efficiency and smoothness of fertilizer application.

Wide applicability: the drum granulator has great adaptability to materials and can be used to produce various types of fertilizers, including urea,ammonium nitrate,ammonium phosphate, etc. This versatility makes it widely used in the fertilizer industry. Low energy consumption: compared with other granulation equipment, the drum granulator has lower energy consumption, is easy to operate and convenient to maintain, and reduces the production cost of water-soluble fertilizer.

Rotary drum granulator is mainly used in all aspects of fertilizer industry, especially in the following aspects: Compound fertilizer production: in the compound fertilizer production process, it is necessary to mix and granulate multiple raw materials. The drum granulator can effectively convert these raw materials into granular compound fertilizer, improving product quality and market competitiveness. Organic fertilizer production: In organic fertilizer production, the drum granulator can process organic wastes into granular fertilizer, which is convenient for transportation, storage and application, and also improves the utilization rate of fertilizer.

Mineral fertilizer processing: For some mineral fertilizers, such as phosphate rock powder, the drum granulator can improve its physical properties through granulation, thus improving its application effect. In short, drum granulator has become the main equipment in fertilizer industry due to its high efficiency, reliability and multi-function. Through continuous innovation of technology, it will play a more important role in improving fertilizer production efficiency, reducing cost and promoting sustainable agricultural development.learn more about drum granulators,Please contact us Fude Machinery!

The machine used to make dog food is usually called Feed puffing machine or pet food processing equipment

View detailsWe offer all kinds of fish feed pellet machines including floating fish feed pellet machine and sinking feed pellet machine.

View detailsFor sheep/goat, cattle/cattle, chickens, rabbits, fish, pigs and other animals, pelleted feed is more conducive to the digestion and absorption of nutrients.

View detailsPelletizing is the process of compressing or molding a material into the shape of a pellet.

View details