Bio-organic fertilizer production line, can it unlock efficiency quality?

221In the burgeoning realm of sustainable agriculture, bio organic fertilizers have emerged as a cornerstone for eco – friendly farming.

View detailsSearch the whole station

Cow manure is a highly beneficial organic material that can be transformed into a nutrient-rich bio fertilizer. This process not only helps in waste management but also promotes sustainable agriculture. If you’re looking to capitalize on this concept, investing in a cow manure bio fertilizer making machine is a prudent decision. However, selecting the right equipment is crucial to ensure efficiency, cost-effectiveness, and desired quality of the output. Here, we’ll delve into the key considerations when choosing the right bio fertilizer machine for your needs.

The first step in selecting a fertilizer making machine is assessing the scale of your operation. Small-scale operations might require compact and semi-automated machines, whereas large commercial enterprises would benefit more from high-capacity, fully automated systems. Understanding your production volume will guide you in choosing equipment that is neither underutilized nor overwhelmed by your processing demands.

Moisture content: high moisture content of raw materials (such as fresh cow dung), it is suitable for choosing roller extruder or column extrusion pelletizing equipment, because it does not need to add additional binder can be pelletized; if the raw material is dry, you can consider other types of equipment.

Organic matter and fiber content: cow dung belongs to fiber raw materials, it is difficult to granulation, the key to granulation is to adjust the fineness and viscosity of the material. The fineness of fermented cow dung should be ≤ 100 mesh, and the finer the basic particles of fine powder materials, the higher the sphericity of the particles, the better the quality of the ball. For high-fiber materials, such as cow dung mixed with wood chips and mushroom slag, a roller granulator can be used, which has better anti-adhesion and abrasion resistance.

Particle strength: If the fertilizers need to be transported over long distances or mechanically applied, preference should be given to extruders or roller granulators, as the particles made by them are of high strength and are not easily broken.

Particle size range: regular particles (2 – 5mm) can be used disc or drum granulator; if you need a special particle size (such as 1mm or less micro-particles), you need a fluidized bed granulator. The granules produced by the churning teeth granulator are spherical in shape, generally between 1.5 – 4mm in size, and the granules are homogeneous, smooth, and of high strength, and the diameter of the granules can be controlled by adjusting the amount of material mixing and the rotating speed of the main shaft.

Stability and reliability: the equipment should be able to maintain stability in long-time operation, reduce the failure rate and ensure production continuity.

Adaptability: the equipment should be able to adapt to changes in different raw material characteristics and production requirements, such as fluctuations in raw material moisture content, organic content, etc.

Convenience of operation: the equipment should be easy to operate and maintain, reduce labor costs and operating difficulties.

When selecting a cow manure bio fertilizer machine, it’s important to consider the specific characteristics and specifications of the equipment. Look into the processing capacity, energy consumption, material compatibility, and the technology employed in the fermentation process. Machines with advanced technology may offer enhanced efficiency and faster conversion rates, thereby improving your overall operational productivity.

The durability of the machine is a critical factor. Check the build quality and materials used in the construction of the cow manure bio fertilizer machine. Stainless steel components are often preferred due to their resistance to corrosion and long lifespan. Additionally, understanding the maintenance requirements and availability of spare parts will prevent unexpected downtimes and prolong the equipment’s life.

Given the focus on sustainability, opt for machines that offer energy-efficient operations. Technologies that minimize power consumption not only reduce operational costs but also have a lower environmental footprint. Moreover, assess the machine’s emission standards to ensure compliance with local environmental regulations.

Finally, the reputation of the supplier or manufacturer is a significant consideration. Look for suppliers with a proven track record in the industry, offering warranties, after-sales support, and comprehensive training services. A reputable supplier is typically more dependable, providing better quality equipment and reliable customer service. Fude Machinery has provided many high-quality bio-fertilizer equipment to customers around the world, which has received rave reviews and is well-known.

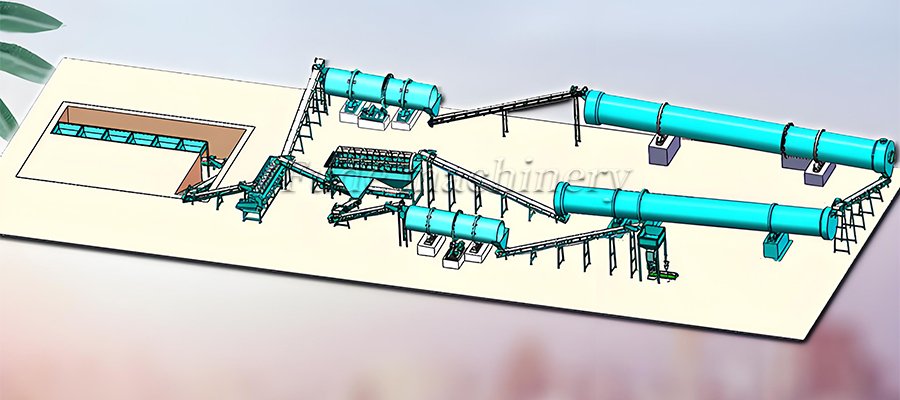

Investing in a cow manure bio fertilizer production line is a promising endeavor for those wishing to harness organic waste for agricultural benefits. By thoroughly evaluating factors such as production scale, machine specifications, durability, energy efficiency, and supplier reputation, you can ensure that you choose the right equipment to meet your operational and environmental goals. With the right machine, you are well on your way to contributing to a greener and more sustainable future.

In the burgeoning realm of sustainable agriculture, bio organic fertilizers have emerged as a cornerstone for eco – friendly farming.

View detailsCompared to chemical fertilizers, chicken manure as an organic fertilizer improves soil structure

View detailsA powdered carbon-based fertilizer production line is a comprehensive system designed to produce fine

View detailsAmong the various types of composting equipment available, the wheel type compost turner stands out with its wide span and high throwing height.

View details