What machines are used to make dog food?

The machine used to make dog food is usually called Feed puffing machine or pet food processing equipment, and this type of equipment can be divided into various types according to the production process and capacity requirements. The following is an introduction from the perspective of equipment classification, core components, functional characteristics and other perspectives:

Core equipment by process

Raw material pretreatment equipment

- Pulverizer: to pulverize meat, grain, vegetables and other raw materials to the required particle size (such as 1-3mm), commonly used hammer blade pulverizer or toothed disc pulverizer.

- Mixer: adopts double-axis paddle type or vertical screw mixer to ensure that the raw materials (such as corn flour, meat powder, vitamin premix) are evenly mixed, mixing uniformity ≥ 95%.

- Puffing machine (key equipment): through high temperature and high pressure (120-180 ℃, 0.8-1.2MPa) to make starch paste, protein denaturation, the formation of porous puffed particles, to enhance the digestibility (up to 80% or more).

Forming and post-processing equipment

- Dryer: adopt mesh belt or fluidized bed dryer to reduce the moisture of puffed granule from 25%-30% to 10%-12% to prolong the shelf life.

- Spraying machine: Spraying grease and flavor agent on the surface of granule to improve palatability, and the amount of grease added can be up to 10%-20%.

- Cooling machine: reduce the temperature of granule to room temperature ±3℃ through counter-current cooler to prevent caking.

- Packing machine: automatic metering packaging machine (such as screw metering type) can realize accurate packaging of 500g-20kg specifications.

Types of equipment by capacity scale

Small production line

- Equipment Configuration: Single Screw Puffer + Simple Dryer + Manual Packing.

- Applicable scenes: pet store, small workshop, suitable for trial production or customized production.

Medium-sized production line

- Equipment Configuration: Twin-screw puffer + Automated mixing/drying/spraying system.

- Applicable Scenario: Medium-sized enterprises, which can produce diversified products such as full-price grain and prescription grain.

Large production line

- Equipment Configuration: Industrial grade twin-screw puffer + Full-automatic control system (PLC) + Online detection (moisture, hardness).

- Applicable scene: large pet food factory, support 24 hours continuous production.

Equipment Selection Points

- Raw material suitability:

- High meat content formula (≥40%) need to choose the twin-screw puffer, to ensure that the meat slurry evenly dispersed.

- Formulations containing bone meal need to be equipped with ultra-micro-grinder (particle size ≤ 80 mesh).

- Process Flexibility:

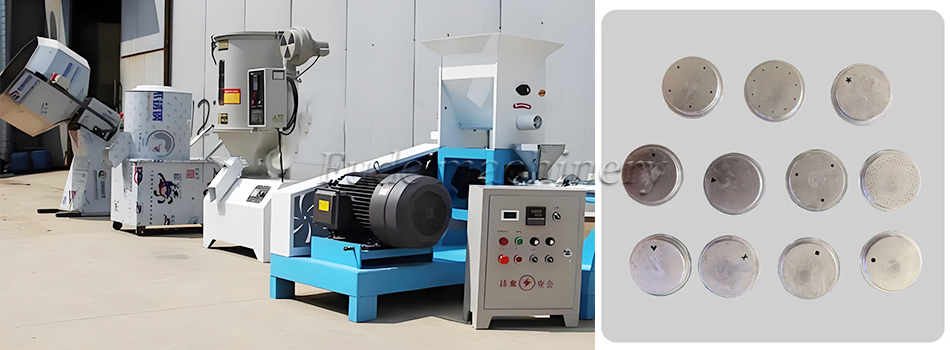

- Modular design equipment allows for quick switching of molds (e.g. round, triangular particles) to meet different pet preferences.

- Energy consumption control:

- The unit energy consumption of the puffing machine should be ≤80kWh/t, and frequency conversion speed control technology is preferred.

Typical production line case

- High-end fresh meat grain production line:

- Process: Fresh meat grinder (8mm orifice plate) → Mixer (add 20% fresh meat) → Twin-screw puffer (160℃) → Vacuum sprayer (add 5% fish oil) → Microwave dryer (10% moisture) → Packaging.

- Characteristics: retaining the nutrition of fresh meat, crispy particles, digestibility of more than 85%.

- Prescription grain production line:

- Configuration: add trace elements automatic measuring system (accuracy ± 0.1%) + low temperature baking machine (90 ℃), suitable for kidney disease, diabetes formula food production.

Industry Trends & Equipment Upgrades

- Intelligent:

- Realize formula management, energy consumption monitoring, quality traceability through MES system, reduce labor cost by 30%.

- Environmentalization:

- The waste heat recovery device of the puffing machine can reduce the exhaust gas temperature from 120℃ to 40℃, and increase the thermal efficiency by 25%.

- Flexible production:

- Quick mold change technology (mold change time ≤ 15 minutes) supports small-lot, multi-variety production and adapts to customized demand.

When choosing dog food production equipment, it is necessary to combine the characteristics of raw materials, product positioning (economic/high-end), capacity requirements and investment budget for comprehensive decision-making. It is recommended to ask for a trial service to ensure that the equipment matches the recipe process. Fude Machinery feed puffer manufacturer is worthy of your trust.