How to Purchase Small Poultry Feed Pellet Machinery at Best Price?

204Fude Machinery can not only provide a single flat die feed pellet mill, but also be used as a package for small and medium-sized feed processing units.

View detailsSearch the whole station

Poultry include many animals, like Chicken, Broiler, Duck, Geese, Pigeon, Emu, Swan, Ostrich, Partridge, Quail, Turkey, etc. For poultry farming, a single kind of feed can’t meet the nutritional needs of animals.

Production practice has proved that only through the scientific collocation of all kinds of feed raw materials can we get a fit feed with sufficient, balanced nutrition and good palatability.

Now, the establishment of poultry feed pellet production plants to produce high-quality livestock feed pellets has become a popular project. Therefore, starting a poultry feed pellet production business is an excellent choice for many investors or farmers to obtain long-term profits.If you are interested in building a feed pellet plant for making feed pellets for your chicken,cattle, sheep,pig and other animals, Fude Machinery can be your best choice!

small feed pellet plant is a small scale pellet feed plant that produces 600-800kg/h and 800-1000kg/h animal feed pellets , mainly applicable to livestock, poultry and fish farmes, hennery, small feed production workshop, and so on. Small feed pellet production equipment including small hammer mill, small feed mixing machine, screw conveyor, storage silo, and small feed pellet mill, feed pellet cooler, feed pellets packaging machine, etc. According to your specific needs and requirements, all the machines in this small animal feed pellet factory are optional. If you are interested in any equipment, please contact us, we will give you the most cost-effective price.

We not only provide small-scale poultry feed pellet manufacturing equipment, but also provide you with a turnkey feed production project, including process design, factory layout, equipment manufacturing, feed factory installation and commissioning, as well as on-site training on electrical control, factory operation, animal feed processing technology .Don’t hesitate to contact us, If you want to know about relevant poultry feed production equipment and complete business plans.

The process of poultry feed production is generally divided into the following steps: feed raw materials receiving and cleaning, raw materials crushing, batching, mixing, pelleting, and packaging of finished feed products.

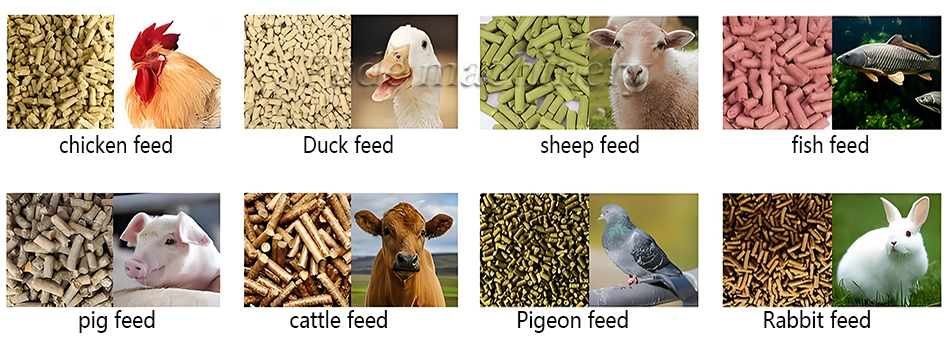

The picture below shows the main poultry feed pellets refined by Fude Machinery animal feed pelleting plant.

Screen machine is normally used in this section. It is mainly to remove impurities from raw materials, such as iron chips and stones. Any questions about equipment selection? Don’t hesitat to contact us!

The crushing of feed raw materials is one of the most important processes in poultry feed processing. This process is to reduce the size of the bulk or granular feed material and crush into the size required for poultry feeding standards. It is related to the quality, yield, electricity consumption and cost of the compound feed. After being crushed, the surface area of the raw material is increased, which is convenient for poultry digestion and absorption. The grain size of broiler chicks feed is better to be medium size, that is, the average diameter of grains is 0.7-0.9mm. With the increase of age, the particle size of comminution can increase correspondingly, and the size for producing laying hen feeds should be above 0.8mm.

It is a process of feeding and weighing various raw materials according to a given formula using a specific batching device, which is an important link to ensure the quality of formulated poultry feed pellets products. Considering that the weighing accuracy and some components may be corrosive, premix additives are usually manually weighed and put directly into the mixing equipment.

Feed mixing process means that the ingredients in the feed formula are mixed uniformly according to the specified weight ratio, making each small part of the whole, even a single feed pellet, has the same proportion of the ingredients as the required formula. The quality of poultry feed mixture is very important for ensuring the quality of compound feed pellets. To achieve uniform mixing in the equipment, micronutrients, such as amino acids, vitamins and minerals, should be pre-mixed to make premix feed. In the premixing process, the larger amount of composition should be added first and then the smaller amount of composition. The mixing time should be determined by testing the mixing uniformity of the poultry feed. The coefficient of variation (CV) of premix shall not be greater than 5%, while the coefficient of variation (CV) of formulated feed shall not be greater than 10%.

Pelleting is an important step when setting up pellets making project or factory.Generally, the feed mixture is added 4-6% of water (normally tempered with steam, suitable for temperature at about 98℃). When entering the Feed Pellet Machine, feed water content increases from air-dried state (moisture content about 10% to 12%) at ambient temperature 。to about 10% to 12% at temperature 80 to 90℃. Water plays a role of lubrication when granulating, and heat causes gelatinization of raw starch on the surface of plant feed ingredients. Feed then is extruded from the outlet of the poultry feed pellet mill, and further raises the feed temperature to nearly 90℃. Therefore, these feed pellets shall be cooled to a slightly higher temperature than the ambient temperature, and at the same time be dried to moisture content below 12% can they go to the next section. For making young poultry feed, like for chick, the feed pellet crumbler is also needed to reduce the pellet size.

After pelletizing, the feed pellet was screened to remove debris and powder, as well as cooled down temperature and moisture, and then stored after packaging. The slag and powder are returned to process.

Fude Machinery is a professional feed pellet equipment supplier. If you want to establish your own poultry feed pellet plant or have any questions about the feed production process, please contact us.

Fude Machinery can not only provide a single flat die feed pellet mill, but also be used as a package for small and medium-sized feed processing units.

View detailsAs an efficient granule making equipment, the drum pelletizer occupies an important position in the fertilizer industry.

View detailsWith the country’s further emphasis on environmental protection, livestock and poultry manure in the breeding industry is also one of the main sources of environmental pollution.

View detailsTurning fine potassium chloride powder into easy-to-use granules offers many advantages for fertilizer producers and farmers.

View details