What Is Feed Pellet Machine?

165Fude Machinery offers different types of feed pellet machines to fit different feed pellet production capacities.

View detailsSearch the whole station

Livestock, cattle, sheep, cow, pig, camel, deer, rabbit, Alpaca, etc. is raised by people for meat, eggs, milk, leather, fur, and wool. Many of these livestock animals can be fed with feed pellets, as feed pellets have higher nutrition density, more comprehensive nutrition, higher economic benefits (animals can digest, absorb and conserve better) and are easier to store and transport than traditional roughage (coarse fodder).

Now, more and more farmers are aware of the benefits of animal feed pellets and tend to make their own livestock feed pellets or buy feed pellets from the market. And, setting up a feed pellet production plant to produce high quality livestock feed pellets has been popular project in breeding industry in many countries, Brazil, United States, China, European Union, Argentina, Australia, Russia, Mexico, Uruguary, Egypt, Ukraine, etc.. Therefore, starting livestock feed pellet manufacturing business has been a great choice for many investors or farmers to gain long-term profits.

Fude Machinery has been committed to providing customers with a comprehensive plan for feed pellet production. We provide full consulting services to help our clients realize their vision of rapid development. Our services include: project evaluation, technical consultation, plant design, equipment manufacturing, installation and commissioning, worker training and other after-sales services.

If you have plan to make feed pellets for your cattle/cow, sheep/goat, pig and others, just contact us directly! Our customized plan for feed pellet production definitely can help you reduce the investment cost and ensure the production efficiency!

The following processing procedures are complete technical process for livestock feed pellet production, but not all procedures are required in practical production. The exact feed pellet manufacturing process are strictly designed by combining requirements of feed pellets, investment cost, capacity and more.

Establishing a livestock feed pellet production line for commercial uses requires a series of processes and a series of feed processing equipment. And the design of the feed manufacturing process will decide the feed pellet machine and other auxiliary equipment. When deciding to build your own feed pellet mill plant for cattle, goat, pig and more, just remember choosing a reliable manufacturer of feed pellet machines can help you to save money and time. For detailed machine price and parameters, please contact us directly!

Livestock feed raw materials vary, they include: long material like crop straw, grains like wheat, maize, and others like oil cake/meal, additives, etc. different raw materials have different storage methods. For example, in complete feed pellet line of large capacity, storage silo is necessary for storing maize, wheat, and other grains.

The impurities in feed raw materials not only affect the quality of feed pellet products, but also directly relate to the feed processing machines and personal safety. In serious case, the whole equipment can be destroyed, which impacts the smooth progress of the feed production, so the impurities must be removed in time. The cleaning equipment of the feed pellet production line is based on screening and magnetic separation equipment. Screening equipment is used to remove large and long impurities such as stones, mud blocks and sacks. The magnetic separator is mainly used to remove iron impurities.

At present, the commonly used batching processes include manual batching, volumetric batching, one warehouse one scale batching, etc. Manual batching is mostly utilized in small feed pellet plant and medium scale feed pellet factory (capacity 1-15T/h). In this batching technology, all feed materials are weighed manually by workers and poured into the mixing machine. As the whole process like measuring and proportioning is all operated by manpower, it needs less equipment investment and low production cost, and has flexible and precise measuring.

There are 2 feed mixing methods: batch mixing and continuous mixing. Batch mixing is to blend all the components together according to the proportion of the formula, and mix them in the periodically running “batch mixer”. This mixing method is convenient for replacing feed formula, and the intermixing between each batch is less, so batch mixing is commonly applied at present. However, as the start and stop operation is complex, the automatic program control is mostly used.

The continuous mixing process is a continuous measurement of all kinds of feed components at the same time respectively and proportionately matched to a stream containing various feed components. When the stream enters a continuous mixer, it is mixed continuously into a uniform flow of material. The advantage of this process is that it can be carried out continuously, easily with comminution and granulation, so the production does not need to operate frequently. but when changing feed formula, the adjustment of the flow is more troublesome and the material residue in the continuous conveying and continuous mixing equipment is more, so the intermixing problem between the two batches of feed is more serious.

Generally livestock feed pellets have 4 kinds: pure forage (grass) feed pellets, complete diet feed pellets, concentrated feed pellets and premix feed pellets.

Livestock feed pellets processing technology & equipment – buy high quality livestock feed pellet machine for feed pellet making: HOT sale livestock feed pellet processing equipment offered by animal feed pellet machine manufacturer or supplier, guide on process of livestock feed pellet production and how to start livestock feed pellet manufacturing business with limited cost in Tanzania, Egypt, Morocco, Ghana, South Korea, etc.

If you want to start your own livestock feed pellet plant, or build a livestock feed pellet factory, please feel free to contact us for most professional guidance!

Fude Machinery offers different types of feed pellet machines to fit different feed pellet production capacities.

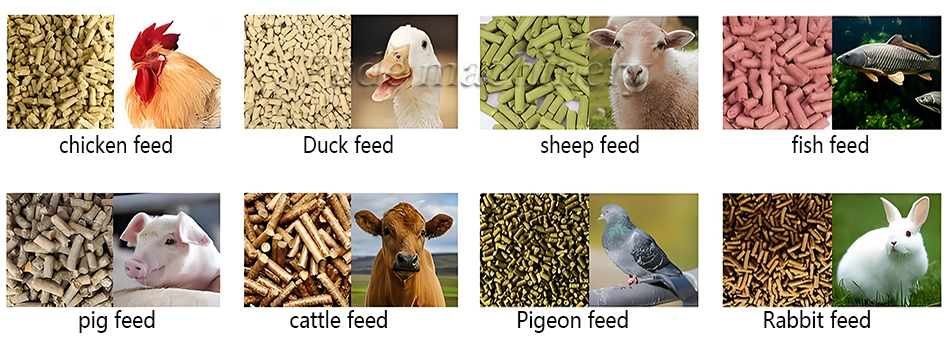

View detailsFor sheep/goat, cattle/cattle, chickens, rabbits, fish, pigs and other animals, pelleted feed is more conducive to the digestion and absorption of nutrients.

View detailsWith the country’s further emphasis on environmental protection, livestock and poultry manure in the breeding industry is also one of the main sources of environmental pollution.

View detailsChicken feed pellets are one of the cost-efficient feed sources and the most preferred chicken feeds for the chickens.

View details