How to build a small poultry feed pellet mill plant?

116Due to increased technology, poultry feed pellet mill is among the new machines in the market.

View detailsSearch the whole station

Due to their easy operation, simple design, and minimal training and maintenance requirements, mini poultry feed pellet production plants are an ideal choice for those who lack the resources or expertise to manage large-scale production facilities. In addition, they can be established quickly and easily at the location of their choice, saving a lot of labor costs. Therefore, as the demand for poultry feed continues to increase, investing in a small-scale poultry feed pellet processing plant is gradually becoming a cost-effective plan.

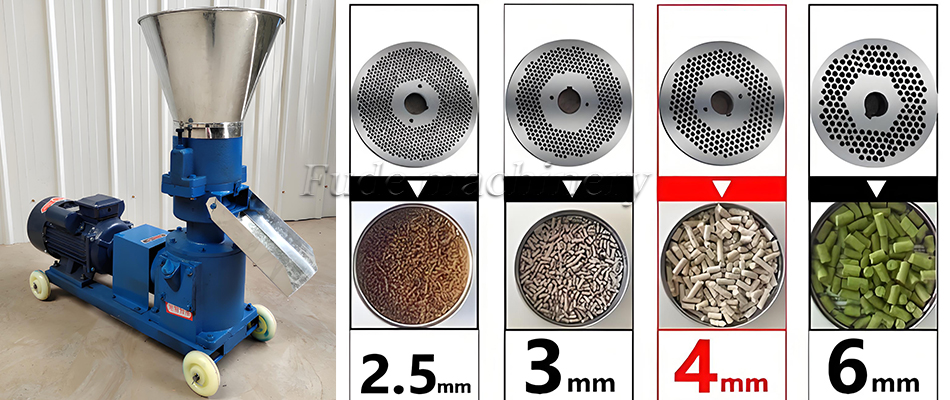

Poultry feed pellet manufacturing machines are feed processing machines that use corn, soybean meal, straw, grass and rice husk as raw materials, which are directly pressed into pellets by crushing the raw materials. Fude Machinery can not only provide a single flat die feed pellet mill, but also be used as a package for small and medium-sized feed processing units. If you are interested in starting a small poultry feed pellet processing business, just feel free to contact us for more detailed information!

Fude Machinery is able to visit your workplace in order to better recommend the best relevant equipment for you, and provide professional technical guidance for the overall layout of your design.

Before starting the process of setting up a mini poultry feed manufacturing plant for farm use, it is important to create a reliable cost plan. This plan should include the cost of poultry feed pellet production machines, labor costs, maintenance and repair costs, and other costs related to factory operations. With a reliable cost plan, it is possible to have a successful small poultry feed manufacturing plant that produces high-quality feed for poultry on the farm.

When planning to set up a small poultry feed manufacturing plant for your own farm, it is important to have the different equipment on the required production line, including feed mixers, feed grinders, feed pelletizers, feed bagging machines and feed silos.

Calculating the cost of feed raw materials is also a key step. There are many types of feed raw materials, and the lack of any nutrient in a chicken’s diet can cause nutritional imbalances and lead to disease. Therefore, under normal feeding management conditions, the formulation of a laying hen’s diet should choose the appropriate protein-energy ratio based on feeding standards.

A simple poultry feed formula is as follows:

| Chick feed | corn 54%, imported fish meal 3%, wheat bran 6%, premix 5%, soybean meal 32% |

| Broiler feed | corn 57.5%, soybean meal 28%, shell meal 0.5%, wheat bran 8%, rice 6% |

| Duckling feed | corn 51%, fish meal 6.5%, bone meal 1%, salt 0.1%, shell meal 1%, wheat bran 10%, broken rice 10%, rapeseed cake 20% |

| Goose feed | 51% corn meal, 15% wheat bran, 15% grass meal, 0.3% salt, 0.7% bone meal, 10% soybean cake, 8% fish meal |

Subject to the actual situation

Fu Tak Machinery Co. small poultry feed pellet machinery is the best choice for any farm use. It is designed to produce high-quality feed pellets at an affordable cost.

Buy the best priced poultry feed pellet processing machine for sale to start small-scale and commerial investment animal feed pellet production from Fude Machinery, the reliable and professional manufacturer or supplier in Tanzania, Egypt, Morocco, Ghana, South Korea, etc., at low cost. Contact us for more information about poultry feed pellet making equipment for sale.

Due to increased technology, poultry feed pellet mill is among the new machines in the market.

View detailsWith the continuous development of agriculture, the issues of soil nutrient circulation and environmental protection are gaining global attention.

View detailsFude Machinery is a professional supplier of cattle feed production lines and equipment, offering one-stop solutions.

View detailsIn modern agricultural production, proper soil management and effective use of fertilizers are key to ensuring high yields and productivity.

View details